Hydraulic Press Frame Structures And Applications

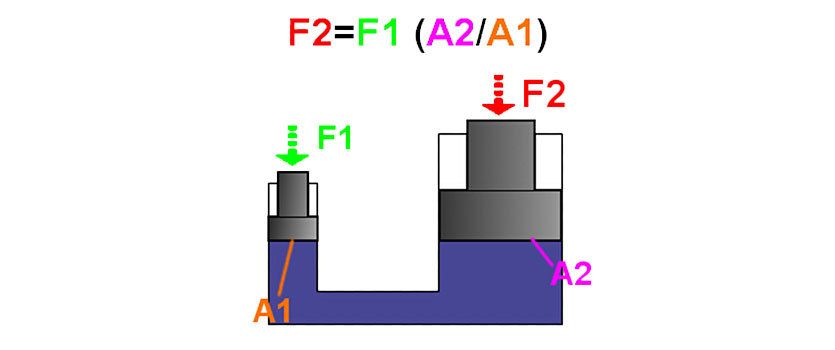

A hydraulic press, also known as a Bramah press, is a press machine that functions by either, fluid pressure or hydraulic pressure. Hydraulic presses function under a dynamic known as Pascal’s principle. The Pascal principle asserts that pressure that is built up throughout any closed system will exert equal force on all areas of the containment.

How Hydraulic Press Works

A hydraulic press is, by today, a device using a hydraulic cylinder to generate a compressive force from hydraulic oil. It contains three main parts. The hydraulic power unit that powers the movement of the press. The electric control unit that controls the movement of the hydraulic press. The main machine body to support and fulfill the requirements of movement.

For operation safety, there is usually a pair of safety light sensors in front of the operative side of the working table. A protective shield will be added to keep non-operators away from the working machine. An emergency stop switch is necessary for any expected accident.

Hydraulic Press Frame Structures And Applications

A hydraulic press can be classified by its hydraulic press frame structure and application. There are several kinds of presses assorting by hydraulic press frame structures. Including two-column hydraulic press, C frame hydraulic press, H frame hydraulic press, four-column hydraulic press, benchtop press and so on.

Assorting by hydraulic press applications, there is hydraulic die cutting press, trimming press, deep drawing press, powder compacting press, straightening press and so on. Nowadays, a hydraulic press machine can have a corresponding mature optimized structure according to its application.

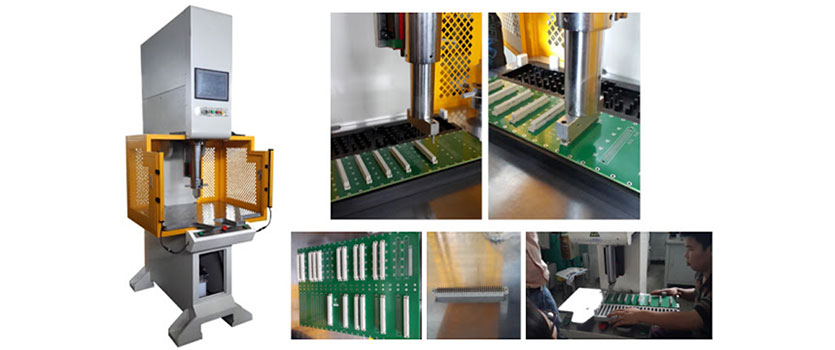

4 post hydraulic press – precision tooling applications. Heavy duty 4-post frame construction provides maximum rigidity.

C-frame presses — also known as gap frame press, for applications which require less space, generally consisting of a single press application.

H-frame presses — also referred to as four-column presses, and they acquire their name for the H-shaped frames.

Laboratory presses — smaller presses that have single applications, and generally used in labs as other testing facilities.

Pneumatic presses — use compressed air to generate energy transfers in order to facilitate and control movement.

Click here to view all lexson hydraulic press frame.

Assembly presses — with the capacity of generating immense pressure to assemble and secure parts together.

Laminating presses — used for the impression of polymers onto other materials, such as paper, lumber or metal.

Heated platen presses — industrial hydraulic hot press. It utilizes tow large, the heated platens for the purpose of bonding, forming or molding a number of different products.

Stamping presses — machines that utilize stamping dies for stamping.

Straightening presses — apply pressure to certain metal for the purpose of straightening it.

Compression molding presses — comprised of two separate plates that pushed together in order to compress the material into the desired mold.