Tag Archive for: servo driven hydraulic press

Jigsaw Puzzle Cutting Machine 500 Ton Hydraulic Press – Lexson Manufacturers

Jigsaw Puzzle Cutting Machine 500 Ton Hydraulic Press – Lexson Manufacturers

LEXSON provides a full range of up-stroke jigsaw puzzle cutting machine from 50 ton up to 3000 ton. LEXSON ‘s jigsaw puzzle cutting machine is exclusively designed and featured for jigsaw puzzle production, as well as plywood jigsaw puzzle die cutting.

With similar tonnages, LEXSON also provides a full range of down-stroke Servo controlled jigsaw puzzle machine, which we have the servo hydraulic control system to replace the conventional hydraulic system. A servo-hydraulic controlled puzzle press machine’s more advantageous, not only in efficiency but also in performance, for more details please refer to servo controlled hydraulic jigsaw puzzle machine.

Click & Contact With Our Engineering Team About Your Unique Jigsaw Puzzle Press Requirements!

LEXSON ‘s jigsaw puzzle cutting machine features:

- Up-stroke acting type

- Hydraulic system mounted at the rear side

- Two-hands press start button

- E-stop button

- Safety light curtains

- Safety mechanical stopper

- Proximity limitation control

- Pressure regulator

- Portable operation console

- Pressure gauge

- Stainless(304) steel slide rails for cutting die to slide IN & OUT

- Flatbed table and slider

- Hydraulic oil chiller

600 Ton Jigsaw Puzzle Machine – lexson machinery

Puzzle Machine 600T Jigsaw Puzzle Die Cutting Press – Lexson Puzzle Machine

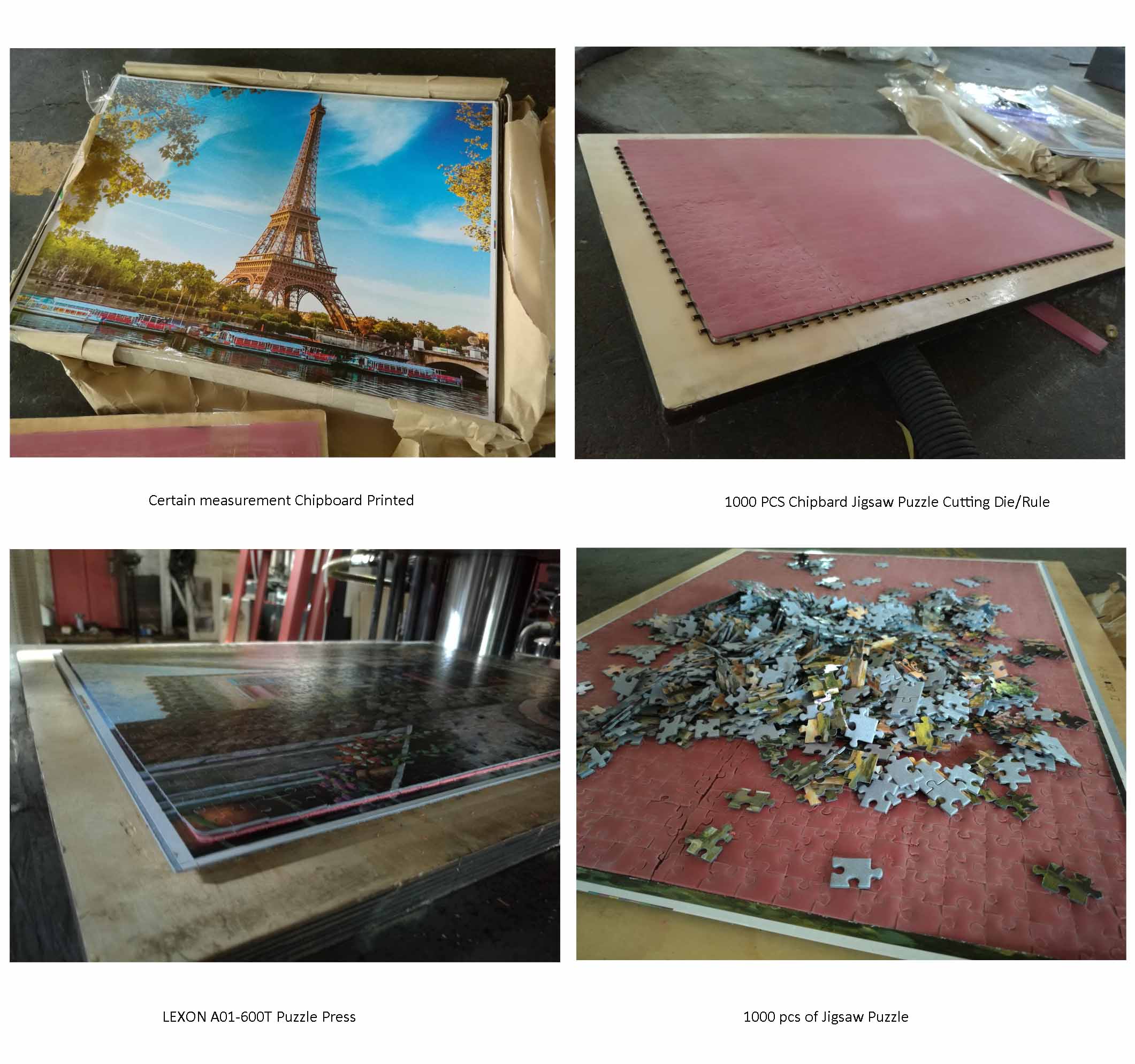

American and Brazilian customers have come for Lexson for 1000 pcs jigsaw puzzle cutting machine. The Lexson-A01 series die cutting press machines are highly optimized-design for different die cutting requirements. Hence, by using Lexson jigsaw puzzle cutting machine, it is more intuitive and easier operation to reduce the need for skilled operators. Due to superrigidity of 4-post frame structure and precision bed-to-ram parallelism, Lexson jigsaw puzzle machines are helping our customers to achieve quality die-cutting parts across the globe.

puzzle-machine

Lexson’s dedicated A01 PRO series die cutting machines are the servo-hydraulic presses. The presses are integrated with precision pressure and position transducers for precision closed-loop control. Firstly, let’s see how the Lexson-A01 PRO 600 ton servo-hydraulic press jigsaw puzzle machine works:

Compared to conventional hydraulic press, the advances of the servo-hydraulic press is obvious:

- First of all, much faster approaching, pressing and return speed

- Secondly, all speed adjustable during the whole stroke

- Furthermore, pressure repeat accuracy: ±1%

- 30%~60% lower energy consumption

- Much less noise level

- All parameters programmable on the central color touchscreen

- Finally, the higher degree of reliability and less need for maintenance during the entire lifetime

puzzle-machine

Lexson-A01 Pro 600 Ton Servo-Hydraulic Press Technical Specification, as below:

| S/N. | Description | Parameters |

| 1 | Model Number | Lexson-A01 600 Ton Pro |

| 2 | Nominal Force | 6000 KN |

| 3 | Daylight Opening | 300 mm |

| 4 | Standard Stroke | 300 mm |

| 5 | Input Power | 220/230/380/480VAC, 3 Phase 50/60 Hz |

| 6 | Work Table Size | 900*950 mm |

| 7 | Table Height | 850 mm |

| 8 | System Pressure | 21 Mpa |

| 9 | Closing Speed | 190~200 mm/s |

| 10 | Slow Speed | 15~18 mm/s |

| 11 | Return Speed | 180~200 mm/s |

puzzle-machine

600-ton servo-hydraulic press jigsaw puzzle machine features:

| Electric Control Cabinet | NEMA style electric cabinet with electric disconnect switch |

| Safety Light Curtain | Front & Back safety light curtains |

| Double Start Buttons | Front Side double start buttons |

| Emergency Stop | Front & Back emergency stop button |

| Safety Mesh Shield | Cover the Left & Right Side of the back table |

| Control | PLC |

| Available Operation Controls | – Manual & Semi-automatic – Stroke adjustable

– Pressure adjustable – Dwell time adjustable |

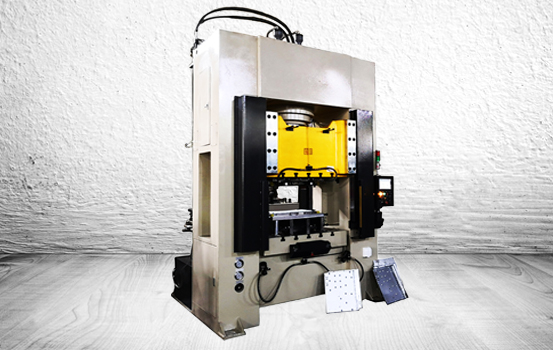

Customized H Frame 200 Ton Servo Hydraulic Press

Customized H Frame 200 Ton Servo Hydraulic Press – Ideal Metal Forming Press Machine

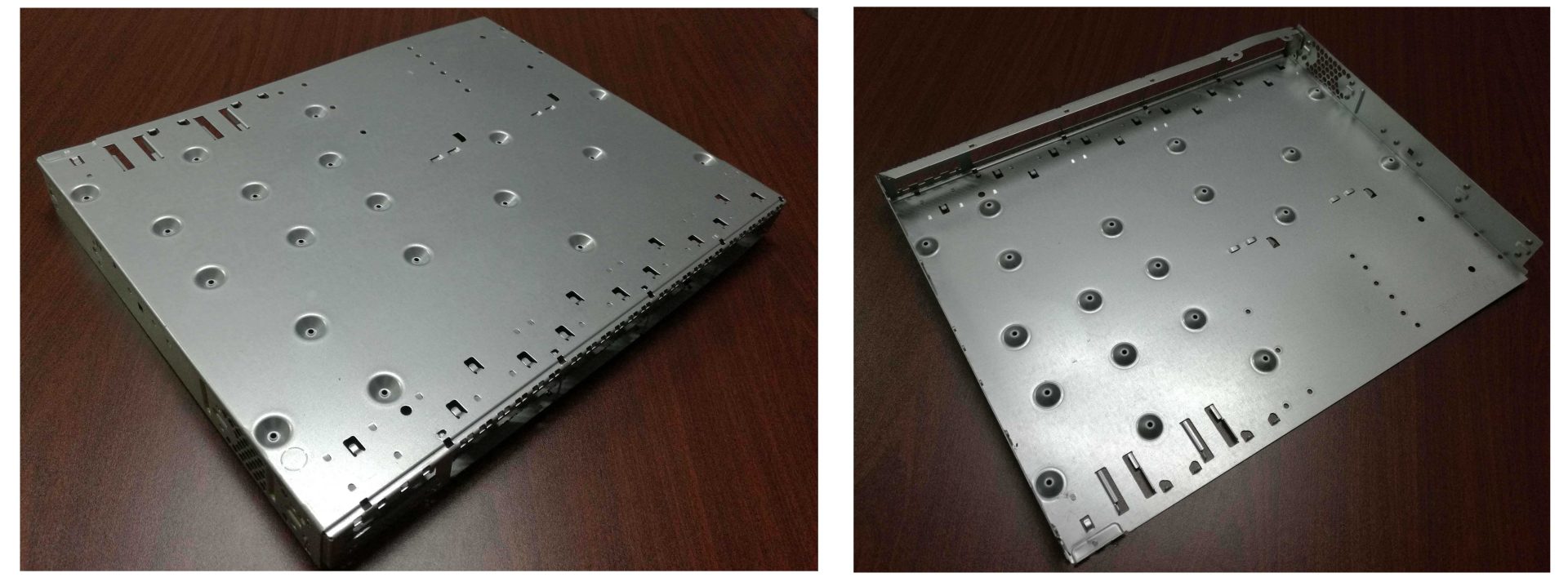

Lexson-P04 PRO customized H frame 200 ton servo hydraulic press is the ideal metal forming press machine for automobile parts and other precision parts. We are dedicated in design and manufacturing of a full range of Servo Hydraulic Press and pure hydraulic press from 100 to 3000 ton.

With our servo hydraulic system, our presses more advantageous in:

- Faster velocity

- Full adjustable velocity

- Adjustable pressure control

- Adjustable slide position

- Less maintenance than a conventional hydraulic press

servo driven hydraulic press

200 Ton Servo Hydraulic Press features:

- PLC control, for high precision control

- 10 Inches Color HMI

- Load Sensorforce feedback & Linear position transducer feedback

- Work mode: Pressure mode & Position mode

- T slotted bed platen and moving platen for mold locking

- Automatically lubricating system

- PLC communication with external equipment

- 50-70% less power consumption than a conventional hydraulic press

- Much lower oil temperature in the working condition than a conventional hydraulic press

customized 200 ton servo press

Safety Measures:

- Double start buttons on the front side of the bed table

- Safety photoelectric light curtain on the front side of the bed table, covering the whole daylight open

- Emergency stop button on the front side of the bed table. Manual reset required

- Pneumatic safety ratchet bar to prevent the sudden fall of the slider. As a result, the avoidance of pending peril will be a great possibility.

- Adjustable protective mechanical position limit switch

- Interlocked safety mesh shield covers the left/right/rear side of bed table, can be opened and removed. When opened, the motor will shut down automatically. Manual reset required

- NEMA style electric control cabinet with electric disconnect switch

- Selector switch with lock only authorized person has the access for operation

- Dual-channel safety monitoring circuit for double start buttons, safety light curtain, emergency stop button, motor on/off, etc.

- Working & Alarming Indicator: triple color indicating light (green/yellow/red) with an alarming buzzer

Customized-H-Frame-200-Ton-Servo-Hydraulic-Press