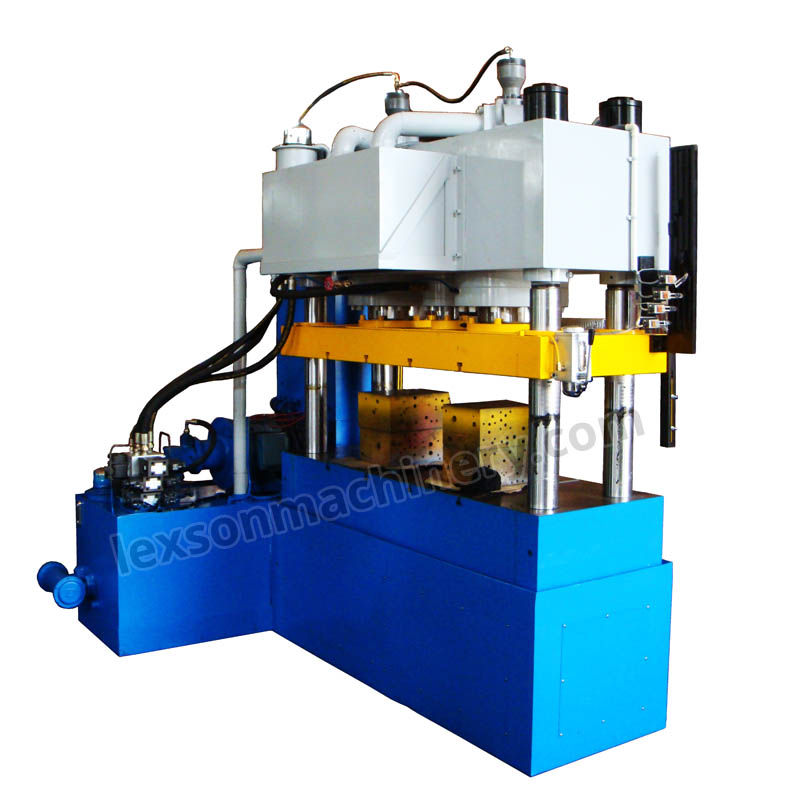

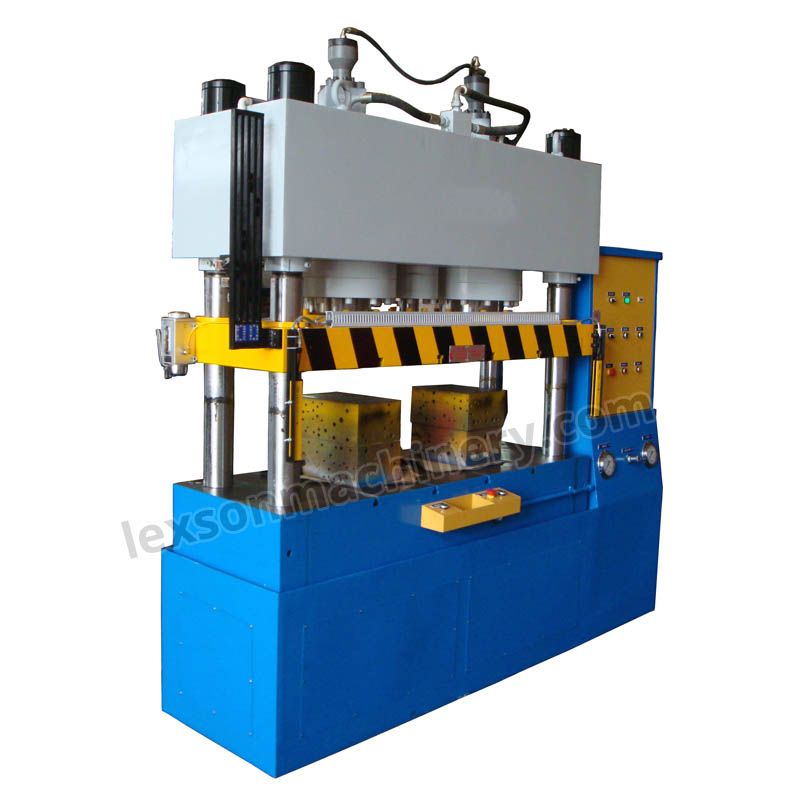

Punching Blanking Press

Product Description

Lexson’s hydraulic punching blanking presses are specially designed for punching and blanking sheet metal parts, especially for sheet metal automotive parts. The punching blanking press is featured with 4-post frame structure. All parameters including pressure, stroke, speed, dwell time and daylight are custom-made to your specific applications. The long bearing length provides the perfect punching and blanking stability and effective resistance to off-center loading.

Precision control is the key to achieve the most cost-effective punching and blanking operation. To ensure the perfect punching and blanking result, we offer the punching blanking press the ability of the entire stroke with precision adjustments. At the same time, we provide the best customized hydraulic press solutions with two pressing control modes for the specific requirements: pressure control mode and position control mode.

Whether you are looking for a punching machine or a blanking machine, Lexson has the best and cost-effective solutions for punching blanking press for you.