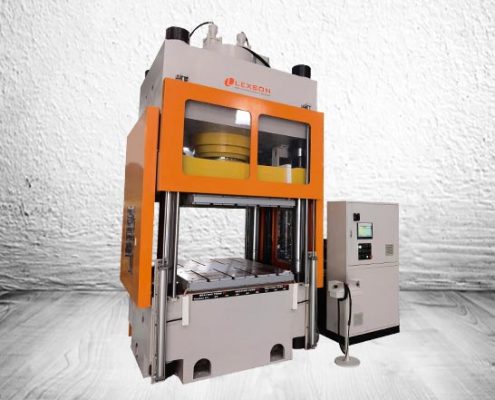

Composites Forming Machine – Lexson Hydraulic Heated Platen Presses

Composites Forming Machine – Lexson Hydraulic Heated Platen Presses

LEXSON provides a full range of composites forming machine – Lexson Hydraulic Heated Platen Presses for Composites Forming process. Built to customer ‘s practical specification from 20 ton up to 1000 ton, LEXSON ‘s composites forming machine hydraulic heated platen press gives uniform pressure distribution and a rather stable temperature required with temperature uncertainty 5 ℃ for better composite molding.

custom-made-composites-forming-machine

Lexson-P06 PRO Composites Forming Machine Hydraulic Heated Platen Press 600 Ton Technical Specifications:

| Nominal force | 6000 KN |

| Bed Table Size | 2000*1400 mm |

| Cylinder Stroke | 400 mm |

| Holding Time | 0~30 min |

| Fast Forward Speed | 150 mm/s |

| Slow Pressing Speed | 25 mm/s |

| Return Speed | 150 mm/s |

| Power | 3 Phase, 480VAC, 60Hz |

| Daylight Opening | 400 mm |

| Temperature | 250℃ |

| Bed Table Height | 800 mm |

.jpg)

custom-made-composites-forming-machine-hydraulic-heated-platen-press-600-ton

Composites Forming Machine – Lexson Hydraulic Heated Platen Presses Features:

*Electric resistive or oil steam heat system

*Water Cooling system

*Independent heating zone for quick heating up and wiring repair

*Multi-zone temperature control achieves good temperature uniformity

*Safety inter-locked shield doors on the left, right and rear sides of work the machine work table

*Pneumatic safety ratchet bar

*10″ HD HMI

*Programmable time and times for exhausting (burping) cycles

*Servo driven hydraulic system available as an option, less noise, save 75% electricity consumption

*Portable operation console(dual run button+E-stop button)

*Safety light curtains