Tag Archive for: servo press

Highly Precision Lexson 1 Ton Electric Servo Press Machine

Highly Precision Lexson 1 Ton Electric Servo Press Machine For Assembly & Press Fitting

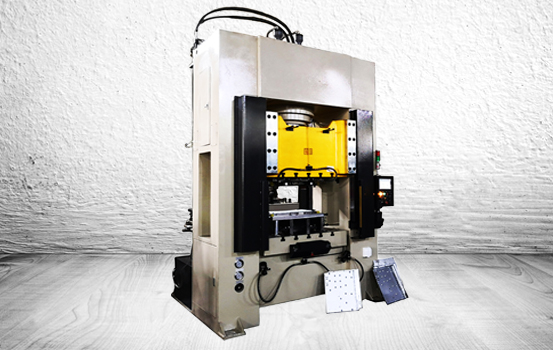

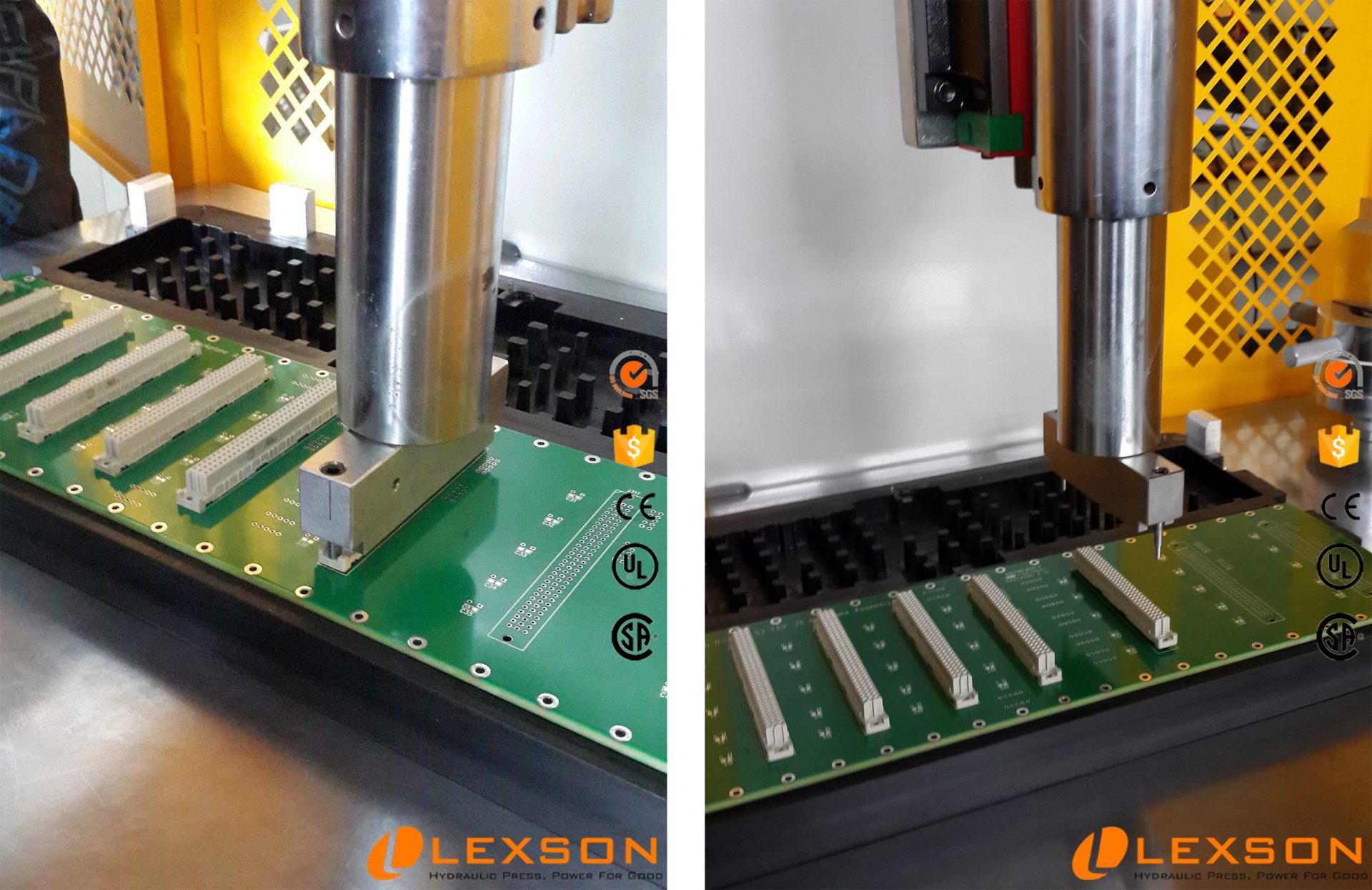

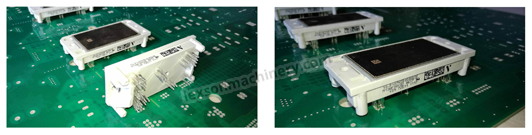

Built with the extremely high degree precision of control for force, dwell time, the distance that a hydraulic press or pneumatic press could never reach for, LEXSON ‘s C frame 1 ton electric servo press machine is custom designed for the processes of precise assembly and press-fitting such as IGBT modules, PCB, precision automobile parts that require the high-degree precision control of assembly force and position.

Specifications of Highly Precision Lexson 1 Ton Electric Servo Press Machine

| Model No. | 1000kgf Servo Press | Structure | C Frame |

| Pressure Output | 1 ton servo press machine | HMI | 10 inches |

| Input Power | 3 Phase AC415VAC, 50Hz | Control Unit | PLC & exclusive control unit |

| Standard Stroke | 200 mm | Drive Mode | Precise AC servo motor |

| Daylight Opening | 300 mm | USB Interface | USB 2.0, download & upload available |

| Bed Table Sizes | 600*600 mm | Die Connector Dia. | Ø20 mm |

| Motor | Servo Motor | Control Mode | 1. Fixed speed, setting position stop

2. Fixed speed, setting load stop 3. Fixed speed, pressing distance stop |

| Fast Forward Speed | 0.1- -200 mm/s | Mold Locking | With T slot on the bed table |

| Detect Speed | 0.1- -30 mm/s | Dwell Time | 0.1~99.9 second |

| Press Speed | 0.1- -50 mm/s | Pressure Repeat Duration | 0.01 F.S |

| Return Speed | 0.1- -200 mm/s | Stroke Repeat Duration | 0.01 mm |

| Working Temperature | 0~40℃ |

electric-servo-presses

1-ton Electric-Servo-Presses

Features of Highly Precision Lexson 1 Ton Electric Servo Press Machine

- Force vs. Position signature monitoring

- Real-time curve line

- 5 points pressing detection

- Specs. setting programmable

- Memory storage & Export data (Production report)

- I/O monitoring

- Alarm information

- 10″ huge HD HMI

- Dual run start button+E-stop button

- Push/pull with equal accuracy (high degree of repeatability, repeat accuracy)

- Ball screw driven, less noise, more energy efficient

- Force & Position control modes

- Three control modes: Fixed speed, setting position stop & Fixed speed, setting load stop & Fixed speed, pressing distance stop

The most common LEXSON P07 Electric Ball Screw Servo Press Machine’s used is Precision Press-fitting of PCB and IGBT Module.

1-ton servo press

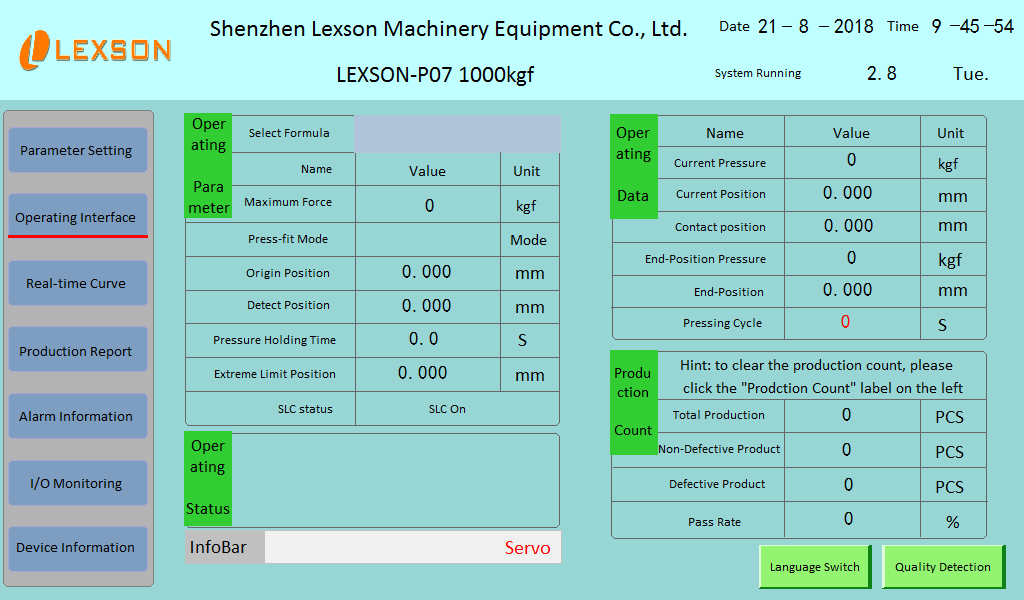

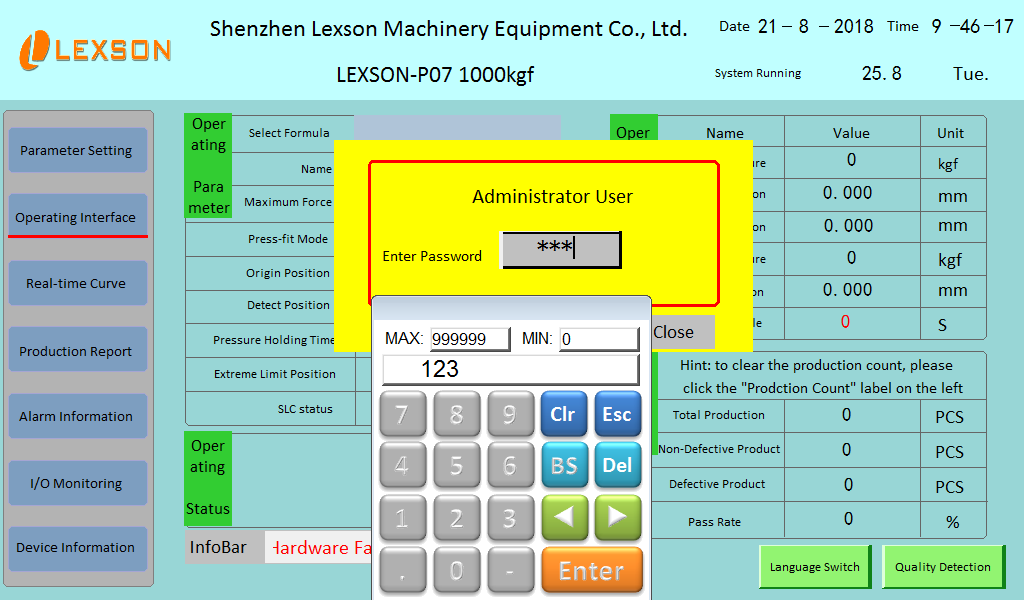

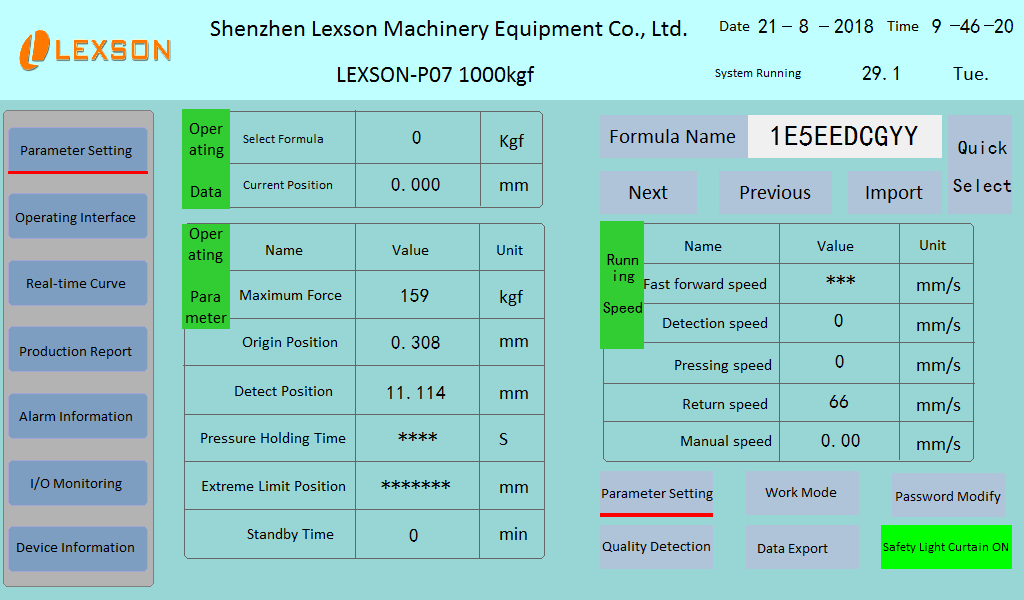

LEXSON-P07 1 Ton Electric servo press machine operation panel screenshot

The operation panel of Servo press machine operation interface:

The operation panel of Servo press machine operation interface:

Fully electric LEXSON-P07 Servo Press provides TENs of fully programmable motion with integrated motion control and monitoring.

Customized H Frame 200 Ton Servo Hydraulic Press

Customized H Frame 200 Ton Servo Hydraulic Press – Ideal Metal Forming Press Machine

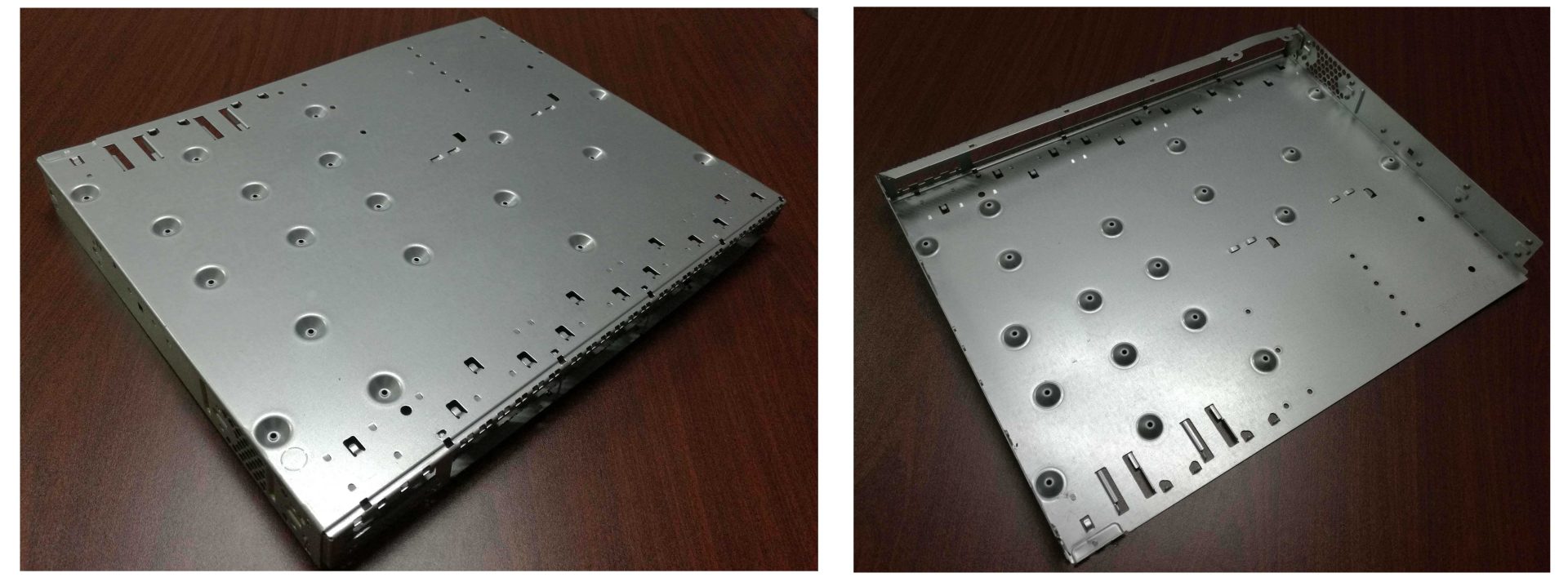

Lexson-P04 PRO customized H frame 200 ton servo hydraulic press is the ideal metal forming press machine for automobile parts and other precision parts. We are dedicated in design and manufacturing of a full range of Servo Hydraulic Press and pure hydraulic press from 100 to 3000 ton.

With our servo hydraulic system, our presses more advantageous in:

- Faster velocity

- Full adjustable velocity

- Adjustable pressure control

- Adjustable slide position

- Less maintenance than a conventional hydraulic press

servo driven hydraulic press

200 Ton Servo Hydraulic Press features:

- PLC control, for high precision control

- 10 Inches Color HMI

- Load Sensorforce feedback & Linear position transducer feedback

- Work mode: Pressure mode & Position mode

- T slotted bed platen and moving platen for mold locking

- Automatically lubricating system

- PLC communication with external equipment

- 50-70% less power consumption than a conventional hydraulic press

- Much lower oil temperature in the working condition than a conventional hydraulic press

customized 200 ton servo press

Safety Measures:

- Double start buttons on the front side of the bed table

- Safety photoelectric light curtain on the front side of the bed table, covering the whole daylight open

- Emergency stop button on the front side of the bed table. Manual reset required

- Pneumatic safety ratchet bar to prevent the sudden fall of the slider. As a result, the avoidance of pending peril will be a great possibility.

- Adjustable protective mechanical position limit switch

- Interlocked safety mesh shield covers the left/right/rear side of bed table, can be opened and removed. When opened, the motor will shut down automatically. Manual reset required

- NEMA style electric control cabinet with electric disconnect switch

- Selector switch with lock only authorized person has the access for operation

- Dual-channel safety monitoring circuit for double start buttons, safety light curtain, emergency stop button, motor on/off, etc.

- Working & Alarming Indicator: triple color indicating light (green/yellow/red) with an alarming buzzer

Customized-H-Frame-200-Ton-Servo-Hydraulic-Press

Lexson-P07 Precision Electric Servo Press Machine

Lexson-P07 Precision Electric Servo Press Machine

The Lexson-P07 precision electric servo press machine is a motion-controlled ball screw press. The electric servo press integrated with pressure and position transducer for precision closed-loop control. The electric servo press machine provides a fully mobile and readily accessible, customized foundation for assembly, test, and lab applications. Unlike conventional hydraulic workstations, the Lexson electric servo press is a completely electric workstation.

The Lexson electric servo press machine is an ideal equipment for assembly

For many precision assembly application, the control force and displacement can have a direct impact on product quality. When press fit an electric connector into the backplane, for example, we will require the very precisely controlled insertion force and displacement. Due to the precision closed-loop control of press-fitting force and press-in displacement in the whole process of the assembly, the Lexson-P07 electric servo press machine is an ideal assembly press for the application.

Compared to conventional pneumatic or hydraulic presses, the Lexson servo press is 80% energy-saving. Furthermore, it’s more environmentally friendly and safe, which best meet the dust-free workshop requirements. The 10” HMI will display the real-time curve of pressing force and displacement of the entire assembly process. Most noteworthy, you can even build up your own quality determine standard by monitoring the pressing pressure and displacement at the end position of the assembly, which is very useful for real-time quality management. All press-fit data is storable, importable and exportable, convenience quick set up for the new press-fit process.