Custom-made Servo Controlled 4-Post 250 Ton Shuttle Table Hydraulic Press

Custom-made Servo Controlled 4-Post 250 Ton Shuttle Table Hydraulic Press

Lexson A01S-250 Ton shuttle table hydraulic press is custom built to be a four-column hydraulic press, controlled by permanent magnet synchronous servo motor, T slotted bed table for mold locking. Compare with a bench top press or a floor stand C frame hydraulic press, the four-post hydraulic press sometimes is not the suitable frame for feeding and unloading, a four-column hydraulic press that has shuttle table helps. With shuttle table moving in and out of the working area, it is much easier for the custom-made servo controlled 4-post 250 ton shuttle table hydraulic press to loading and unloading during the working cycle time.

250 Ton Servo Controlled Slide Table Hydraulic Press

Specifications of Custom-made Servo Controlled 4-Post 250 Ton Shuttle Table Hydraulic Press

| Model No. | Lexson A01S-250T |

| Structure | Four Column |

| Drive Mode | Servo Motor |

| Nominal Force | 2500 KN |

| Table Size | 800*600 mm |

| Daylight Open | 700 |

| Stroke | 500 mm |

| System Pressure | 250 bar |

| Motor | 23 KW |

| Power Supply | AC 3 Phase 415V |

| Rated Current | 35A |

| Shuttle Table Stroke | 600 |

| Cylinders | 3 cylinders(high speed+pressing ) |

250 Ton Servo Controlled Hydraulic press with sliding table (7)

The Custom-made Servo Controlled 4-Post 250 Ton Shuttle Table Hydraulic Press has these advantages:

- Utilizing permanent magnet synchronous servo motor, the machine ‘s quiet

- 50-70% less electricity consumption than conventional hydraulic press machine

- Hydraulic decompression control

- Safe operation

- Position control

- Time control

- Pressure control

- All these controls on HMI

- 10” HD Human-machine Interface

- NEMA enclosures

- Industry standard components

- Portable operation console

- Two-hand start button

- Emergency stop button

- Manual & Semi-automatic

- Slide rails for slide table to slide in and out

- Siemens 10” HMI & PLC

Precision Press Machine Servo Hydraulic 10 Ton C Frame Press – Lexson

Precision press machine servo-hydraulic 10 ton C frame press structure ‘s built to be:

- Module design, compact, least space occupation

- Biggest space to access the working area

- Overall welded structure, more stable and offers best load stability

- Deliver outstanding precision & reliable operation

- Guided slider, designed for precision assembling, press-fitting

- Program press profiles via 10″ huge high-density color HMI

- Siemens HMI operation language: English

- Schneider electrical parts

- Siemens PLC

- Utilization of Permanent magnet synchronous servo motor, intelligent energy-saving servo driven system, advanced in 50-70% less energy consumption compared with other conventional hydraulic systems

- Fager linear position sensor, accuracy: ±0.03 mm

- Hydraulics: Bosch Rexroth

- Left, right and front sides of bed table covered by two pairs of safety light curtains

Click & Contact With Our Engineering Team About Your Unique C Frame Precision Press Requirements!

Precision Press Machine Servo Driven 10 Ton C Frame Press Machine- Lexson

Lower threaded rod electric cylinder:

- Independent programming system

- Independent high-density screen display(HMI: 10″ Siemens)

- All profile programmable via HMI

Precision Press Machine Servo Driven 10T Press Machine – Lexson Technical specifications:

| Model No. | Lexson-P03-10Ton | |

| Machine name | Precision-press-machine-Servo-Driven-Lexson-P03-10T | |

| Capacity | 10 Ton | |

| Table size | 500*400 mm | |

| Cylinder stroke | 350 mm | |

| Throat Depth | 150 mm | |

|

Master Cylinder Speed |

Close | 200 mm/s |

| Slow | 40 mm/s | |

| Return | 200 mm/s | |

| Table height | 750 mm | |

| Motor | 4 KW | |

| Power supply | 3 Phase 230VAC, 50Hz | |

| Lower cylinder | threaded rod electric cylinder | |

| Lower cylinder pressure accuracy | 1Bar | |

| Lower cylinder pressure | 2 ton | |

| Lower cylinder stroke | 200 mm | |

| Repeat positioning accuracy | ±0.02 mm | |

Hydraulic Deep Drawing Press Machine 1000 Ton – LEXSON

Hydraulic Deep Drawing Press Machine 1000 Ton – LEXSON ‘s standard hydraulic deep drawing press machine ranges from 45 to 1000 tons, features compact and intuitive design. Heavy duty 4-post and stress-relieved frame body are extremely rigid and minimum deflection to provide perfect rigidity and durability. Well-forged and precise-polished heavy-duty cylinder remain highly reliable when machine running at the high load condition.

Additionally, Lexson can work directly with your tooling suppliers from every beginning of your deep drawing project, and ensure that the press is optimized and workable with your tooling.

Custom-made-hydraulic-press-machine-1000 ton

Hydraulic Deep Drawing Press Machine Features & Benefits:

- Top mounted hydraulic system(totally closed by safety shields)

- NEMA type electrical control cabinet apart from machine main body

- Portable operation console(dual run button+E-stop button)

- Pressure Sensor

- Linear Position Sensor

- Safety light curtain

- T slotted channel on moving platen and bed table

- 10″ Color HMI(Language: Chinese & English)

- Pneumatic safety ratchet bar

- Servo controlled hydraulic control system(Servo controlled hydraulic deep drawing press machine) as an option

Metal Stamping Press Machine – Lexson Press Made In China

Metal Stamping Press Machine – Lexson Press Made In China

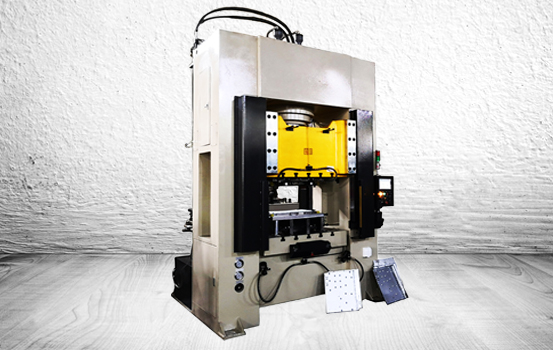

LEXSON provides a full range of H frame metal stamping press machine from 50 ton up to 1000 ton, that utilizes advanced Servo Hydraulic Press System with the following features:

- PLC control, for high precision control

- 10 Inches Color HMI

- Pressure repeat accuracy: ±1%

- Plates parallelism: ±04%

- Table flatness: ±025 mm

- Load Sensorforce feedback & Linear position transducer feedback

- Work mode: Pressure mode & Position mode

- T slotted bed platen and moving platen for mold locking

- Automatic lubrication system

- PLC communication with external equipment

- Programmable operation

- 50-70% less power consumption than a conventional hydraulic press

- Much lower oil temperature in the working condition than a conventional hydraulic press

- Top mounted hydraulic system

- Lifting rings on the top plate for easier machine locating

metal stamping press machine

With LEXSON ‘s servo-hydraulic system, LEXSON ‘S presses are more advantageous in:

- Faster velocity

- Full adjustable velocity

- Adjustable pressure control

- Adjustable slide position

- Requires significantly less maintenance than a conventional hydraulic press

metal stamping press machine

Safety Measures:

- Double start buttons on the front side of the bed table

- Safety photoelectric light curtain on the front side of the bed table, covering the whole daylight open

- Emergency stop button on the front side of the bed table, manual reset required

- Pneumatic safety ratchet bar to prevent the sudden fall of the slider, in case of any error happened to the hydraulic system

- Adjustable protective mechanical position limit switch

- Interlocked safety mesh shield covers the left/right/rear side of bed table, can be opened and removed. When opened, the motor will shut down automatically, manual reset required

- NEMA style electric control cabinet with electric disconnect switch

- Selector switch with lock only authorized person has the access for operation

- Dual-channel safety monitoring circuit for double start buttons, safety light curtain, emergency stop button, motor on/off, etc.

- Working & Alarming Indicator: triple color indicating light (green/yellow/red) with an alarming buzzer

metal stamping press machine

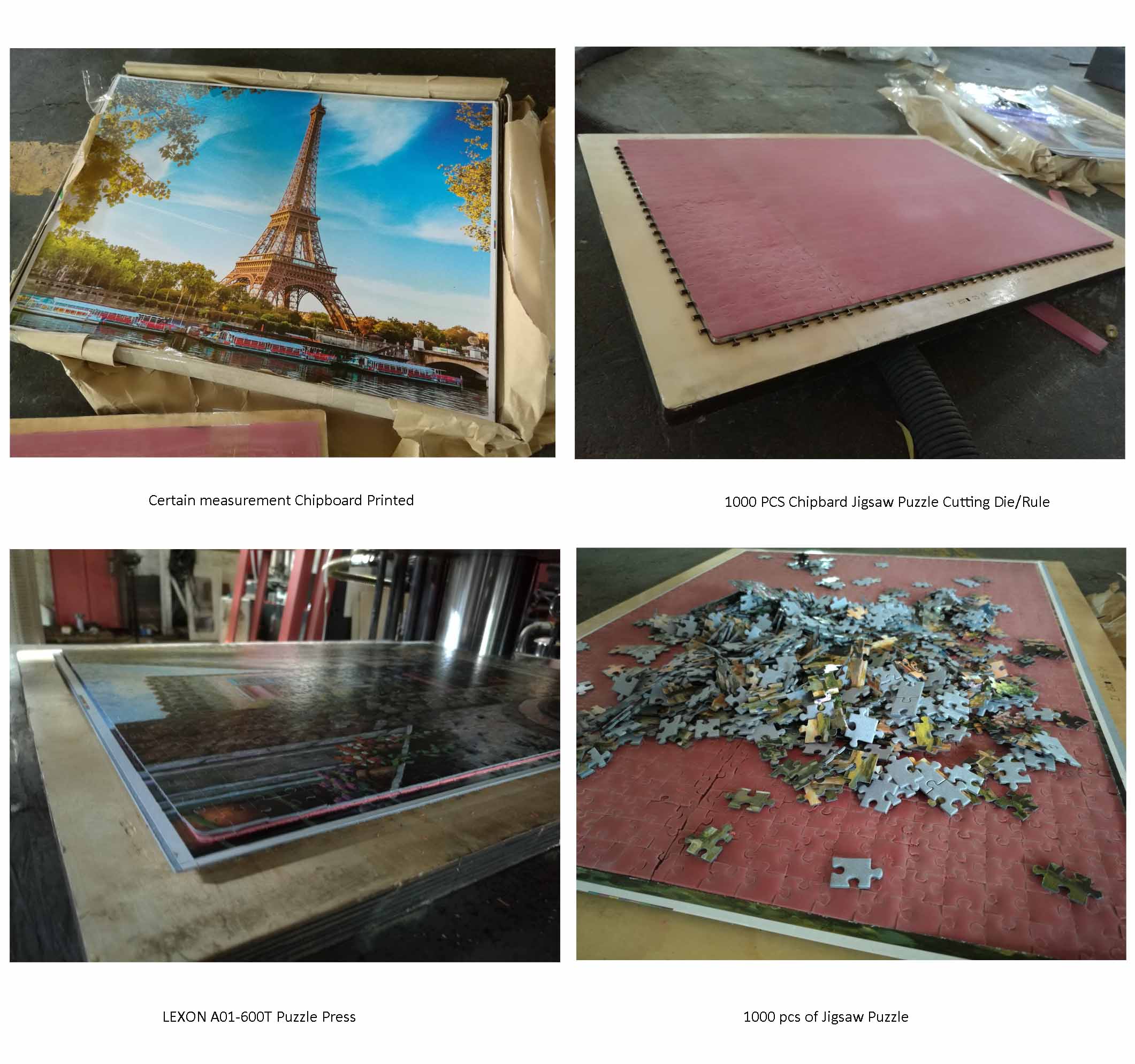

600 Ton Jigsaw Puzzle Machine – lexson machinery

Puzzle Machine 600T Jigsaw Puzzle Die Cutting Press – Lexson Puzzle Machine

American and Brazilian customers have come for Lexson for 1000 pcs jigsaw puzzle cutting machine. The Lexson-A01 series die cutting press machines are highly optimized-design for different die cutting requirements. Hence, by using Lexson jigsaw puzzle cutting machine, it is more intuitive and easier operation to reduce the need for skilled operators. Due to superrigidity of 4-post frame structure and precision bed-to-ram parallelism, Lexson jigsaw puzzle machines are helping our customers to achieve quality die-cutting parts across the globe.

puzzle-machine

Lexson’s dedicated A01 PRO series die cutting machines are the servo-hydraulic presses. The presses are integrated with precision pressure and position transducers for precision closed-loop control. Firstly, let’s see how the Lexson-A01 PRO 600 ton servo-hydraulic press jigsaw puzzle machine works:

Compared to conventional hydraulic press, the advances of the servo-hydraulic press is obvious:

- First of all, much faster approaching, pressing and return speed

- Secondly, all speed adjustable during the whole stroke

- Furthermore, pressure repeat accuracy: ±1%

- 30%~60% lower energy consumption

- Much less noise level

- All parameters programmable on the central color touchscreen

- Finally, the higher degree of reliability and less need for maintenance during the entire lifetime

puzzle-machine

Lexson-A01 Pro 600 Ton Servo-Hydraulic Press Technical Specification, as below:

| S/N. | Description | Parameters |

| 1 | Model Number | Lexson-A01 600 Ton Pro |

| 2 | Nominal Force | 6000 KN |

| 3 | Daylight Opening | 300 mm |

| 4 | Standard Stroke | 300 mm |

| 5 | Input Power | 220/230/380/480VAC, 3 Phase 50/60 Hz |

| 6 | Work Table Size | 900*950 mm |

| 7 | Table Height | 850 mm |

| 8 | System Pressure | 21 Mpa |

| 9 | Closing Speed | 190~200 mm/s |

| 10 | Slow Speed | 15~18 mm/s |

| 11 | Return Speed | 180~200 mm/s |

puzzle-machine

600-ton servo-hydraulic press jigsaw puzzle machine features:

| Electric Control Cabinet | NEMA style electric cabinet with electric disconnect switch |

| Safety Light Curtain | Front & Back safety light curtains |

| Double Start Buttons | Front Side double start buttons |

| Emergency Stop | Front & Back emergency stop button |

| Safety Mesh Shield | Cover the Left & Right Side of the back table |

| Control | PLC |

| Available Operation Controls | – Manual & Semi-automatic – Stroke adjustable

– Pressure adjustable – Dwell time adjustable |

Composites Forming Machine – Lexson Hydraulic Heated Platen Presses

Composites Forming Machine – Lexson Hydraulic Heated Platen Presses

LEXSON provides a full range of composites forming machine – Lexson Hydraulic Heated Platen Presses for Composites Forming process. Built to customer ‘s practical specification from 20 ton up to 1000 ton, LEXSON ‘s composites forming machine hydraulic heated platen press gives uniform pressure distribution and a rather stable temperature required with temperature uncertainty 5 ℃ for better composite molding.

custom-made-composites-forming-machine

Lexson-P06 PRO Composites Forming Machine Hydraulic Heated Platen Press 600 Ton Technical Specifications:

| Nominal force | 6000 KN |

| Bed Table Size | 2000*1400 mm |

| Cylinder Stroke | 400 mm |

| Holding Time | 0~30 min |

| Fast Forward Speed | 150 mm/s |

| Slow Pressing Speed | 25 mm/s |

| Return Speed | 150 mm/s |

| Power | 3 Phase, 480VAC, 60Hz |

| Daylight Opening | 400 mm |

| Temperature | 250℃ |

| Bed Table Height | 800 mm |

.jpg)

custom-made-composites-forming-machine-hydraulic-heated-platen-press-600-ton

Composites Forming Machine – Lexson Hydraulic Heated Platen Presses Features:

*Electric resistive or oil steam heat system

*Water Cooling system

*Independent heating zone for quick heating up and wiring repair

*Multi-zone temperature control achieves good temperature uniformity

*Safety inter-locked shield doors on the left, right and rear sides of work the machine work table

*Pneumatic safety ratchet bar

*10″ HD HMI

*Programmable time and times for exhausting (burping) cycles

*Servo driven hydraulic system available as an option, less noise, save 75% electricity consumption

*Portable operation console(dual run button+E-stop button)

*Safety light curtains

Highly Precision Lexson 1 Ton Electric Servo Press Machine

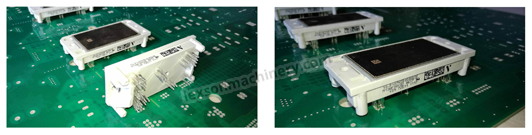

Highly Precision Lexson 1 Ton Electric Servo Press Machine For Assembly & Press Fitting

Built with the extremely high degree precision of control for force, dwell time, the distance that a hydraulic press or pneumatic press could never reach for, LEXSON ‘s C frame 1 ton electric servo press machine is custom designed for the processes of precise assembly and press-fitting such as IGBT modules, PCB, precision automobile parts that require the high-degree precision control of assembly force and position.

Specifications of Highly Precision Lexson 1 Ton Electric Servo Press Machine

| Model No. | 1000kgf Servo Press | Structure | C Frame |

| Pressure Output | 1 ton servo press machine | HMI | 10 inches |

| Input Power | 3 Phase AC415VAC, 50Hz | Control Unit | PLC & exclusive control unit |

| Standard Stroke | 200 mm | Drive Mode | Precise AC servo motor |

| Daylight Opening | 300 mm | USB Interface | USB 2.0, download & upload available |

| Bed Table Sizes | 600*600 mm | Die Connector Dia. | Ø20 mm |

| Motor | Servo Motor | Control Mode | 1. Fixed speed, setting position stop

2. Fixed speed, setting load stop 3. Fixed speed, pressing distance stop |

| Fast Forward Speed | 0.1- -200 mm/s | Mold Locking | With T slot on the bed table |

| Detect Speed | 0.1- -30 mm/s | Dwell Time | 0.1~99.9 second |

| Press Speed | 0.1- -50 mm/s | Pressure Repeat Duration | 0.01 F.S |

| Return Speed | 0.1- -200 mm/s | Stroke Repeat Duration | 0.01 mm |

| Working Temperature | 0~40℃ |

electric-servo-presses

1-ton Electric-Servo-Presses

Features of Highly Precision Lexson 1 Ton Electric Servo Press Machine

- Force vs. Position signature monitoring

- Real-time curve line

- 5 points pressing detection

- Specs. setting programmable

- Memory storage & Export data (Production report)

- I/O monitoring

- Alarm information

- 10″ huge HD HMI

- Dual run start button+E-stop button

- Push/pull with equal accuracy (high degree of repeatability, repeat accuracy)

- Ball screw driven, less noise, more energy efficient

- Force & Position control modes

- Three control modes: Fixed speed, setting position stop & Fixed speed, setting load stop & Fixed speed, pressing distance stop

The most common LEXSON P07 Electric Ball Screw Servo Press Machine’s used is Precision Press-fitting of PCB and IGBT Module.

1-ton servo press

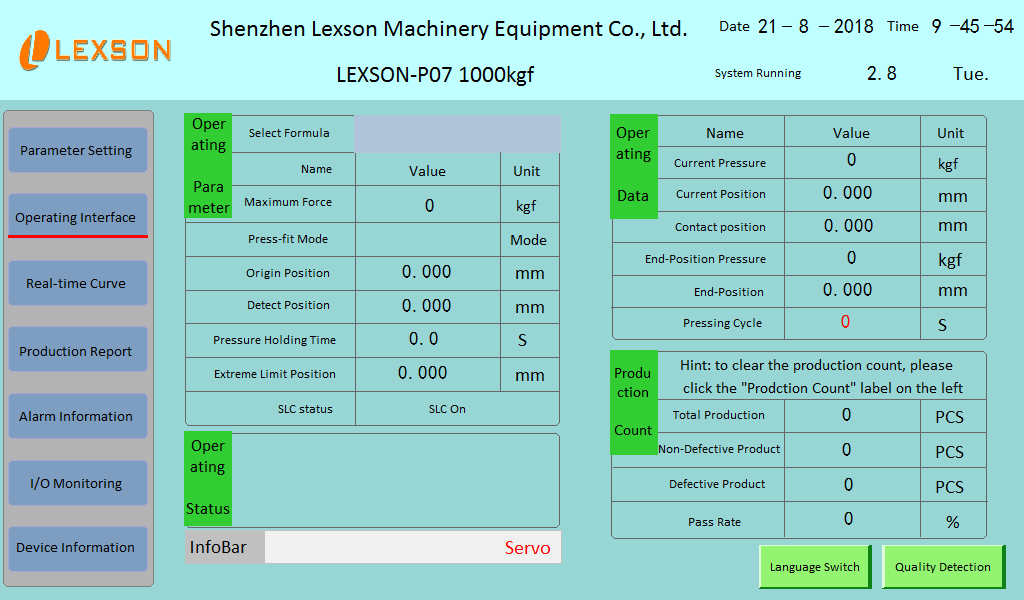

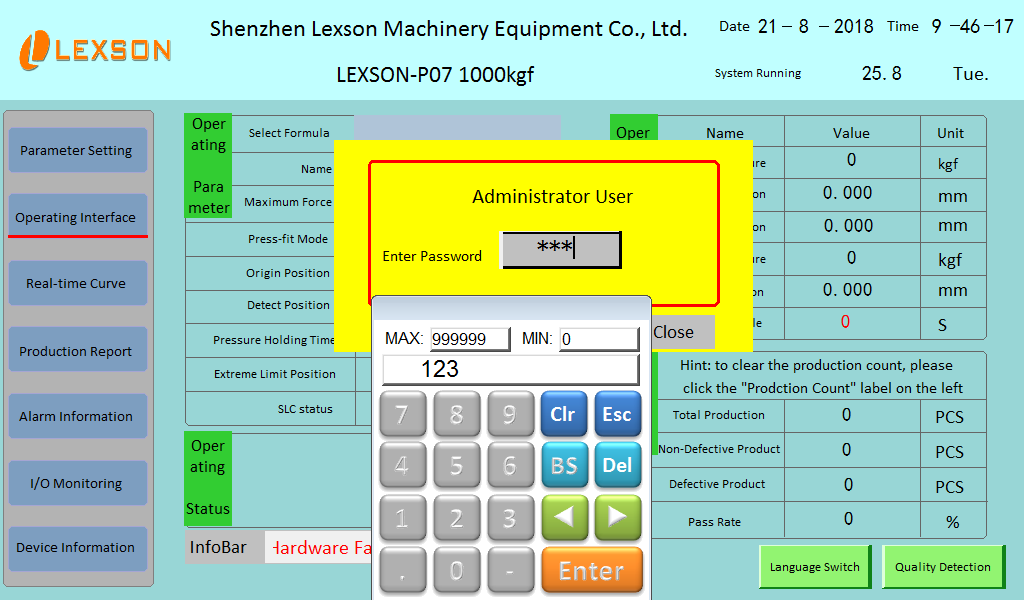

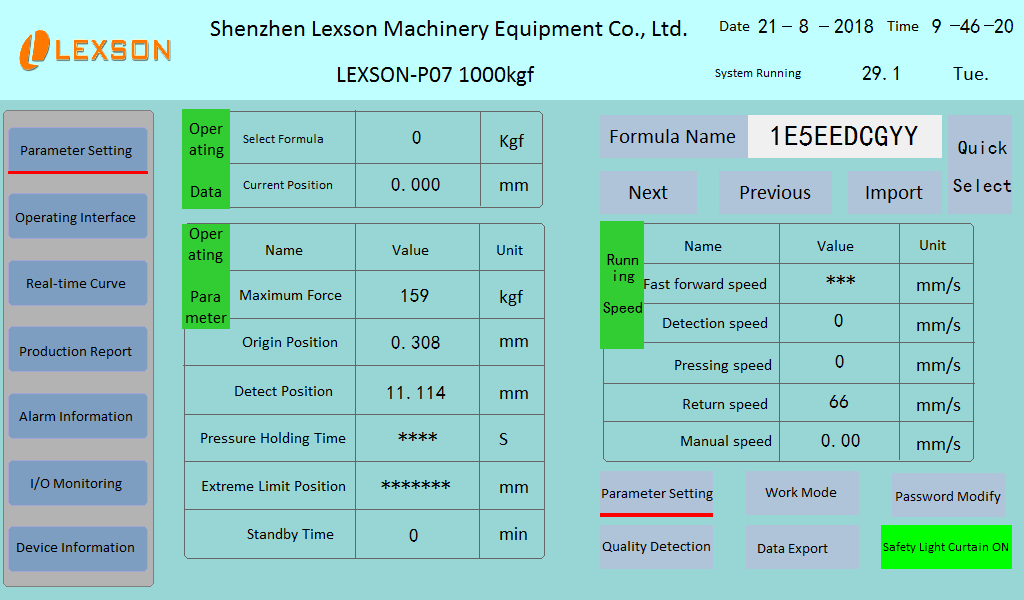

LEXSON-P07 1 Ton Electric servo press machine operation panel screenshot

The operation panel of Servo press machine operation interface:

The operation panel of Servo press machine operation interface:

Fully electric LEXSON-P07 Servo Press provides TENs of fully programmable motion with integrated motion control and monitoring.

20 Ton 4-Post Heated Platen Press Leading Manufacturer

20 Ton 4-Post Heated Platen Press Leading Manufacturer

First of all, let’s see how Lexson 20 ton 4-post heated platen press works:

More heavy-duty 600 ton heated platen press available from Lexson:

Lexson offers a wide range of heated platen press with single and multi-daylight. Load ranges from 10 ton up to 1000 ton. Due to the stable uniform distribution of pressure and heating temperature, the Lexson heated platen presses are suitable for most of the hot forming process. Therefore, you can see our presses widely used in the production of laminates, compression molding (large scale heat compression molding machine), composite panel and molded rubber products worldwide. The Lexson 4-post heated platen press can also be a suitable lab press for battery coil test. Furthermore, lab tests requiring different molding temperature and pressure condition will probably need a similarly Lexson-P06 PRO heated platen press.

20 ton 4-post heated platen press

Technical specifications of Lexson 20 ton 4-post heated platen press:

| Model No. | Lexson-P06 PRO 4-post Heated Platen Presses 20 Ton | Height of Bed Table Above Floor | 780 mm |

| Pressure Output | 200 KN | Fast Forward Speed | 120 mm/s |

| Input Power | AC230VAC, 3 Phase | Slow Pressing Speed | 25 mm/s |

| Daylight Opening | 400 mm | Return Speed | 120 mm/s |

| Standard Stroke | 300 mm | Heat Temperature | 300℃ |

| Bed Table Sizes | 600*400 mm | Dwell time(Adjustable) | 0~30 minutes |

4 post heated platen presses

20 ton 4-post heated platen press features:

(The 4-post heated platen press can be custom built directly to your specification and requirements)

| HMI | 10 Inches Color Touch Screen |

| Self-lubricated Bushings | Yes |

| Driven Type | Hydraulic |

| Structure | With upper and lower heat platens |

| Control | PLC |

| Temperature Control System | Yes |

| Heat Insulation Platen | Yes |

| Double Start Buttons | Yes |

| Emergency Stop Button | Yes |

| Safety Light Sensors | Cover the whole daylight |

| Safety Mesh Shield | Cover left / right/rear sides of the bed table |

| Mold Locking | With T slot on the bed table and the slide table |

| Load Cells | Yes |

| Displacement Transducer | Yes |

| NEMA Control Cabinet | Yes, with electric disconnect switch |

| Oil Leakage Strategy | – Oil leakage audible alarming

-Hydraulic oil collecting grooves on slide table and bed table |

| Dual Channel Safety Circuit | Yes |

| Pneumatic Safety Ratchet Bar | Yes |

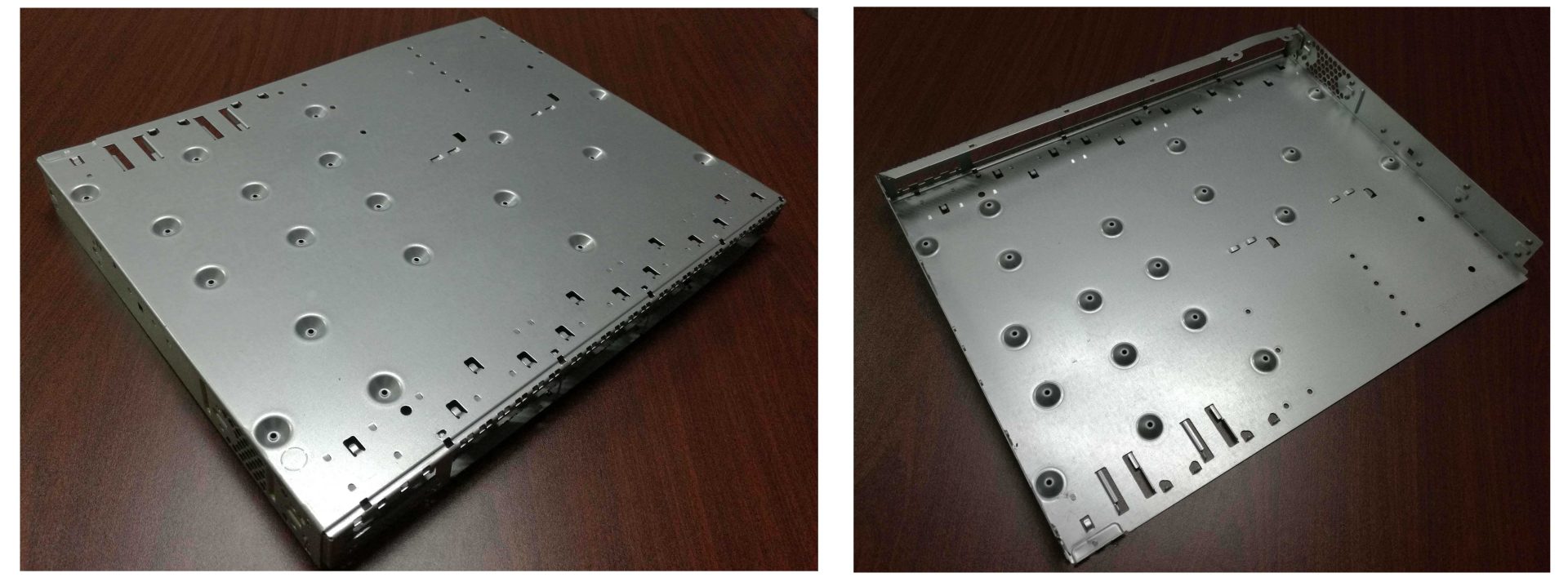

Customized H Frame 200 Ton Servo Hydraulic Press

Customized H Frame 200 Ton Servo Hydraulic Press – Ideal Metal Forming Press Machine

Lexson-P04 PRO customized H frame 200 ton servo hydraulic press is the ideal metal forming press machine for automobile parts and other precision parts. We are dedicated in design and manufacturing of a full range of Servo Hydraulic Press and pure hydraulic press from 100 to 3000 ton.

With our servo hydraulic system, our presses more advantageous in:

- Faster velocity

- Full adjustable velocity

- Adjustable pressure control

- Adjustable slide position

- Less maintenance than a conventional hydraulic press

servo driven hydraulic press

200 Ton Servo Hydraulic Press features:

- PLC control, for high precision control

- 10 Inches Color HMI

- Load Sensorforce feedback & Linear position transducer feedback

- Work mode: Pressure mode & Position mode

- T slotted bed platen and moving platen for mold locking

- Automatically lubricating system

- PLC communication with external equipment

- 50-70% less power consumption than a conventional hydraulic press

- Much lower oil temperature in the working condition than a conventional hydraulic press

customized 200 ton servo press

Safety Measures:

- Double start buttons on the front side of the bed table

- Safety photoelectric light curtain on the front side of the bed table, covering the whole daylight open

- Emergency stop button on the front side of the bed table. Manual reset required

- Pneumatic safety ratchet bar to prevent the sudden fall of the slider. As a result, the avoidance of pending peril will be a great possibility.

- Adjustable protective mechanical position limit switch

- Interlocked safety mesh shield covers the left/right/rear side of bed table, can be opened and removed. When opened, the motor will shut down automatically. Manual reset required

- NEMA style electric control cabinet with electric disconnect switch

- Selector switch with lock only authorized person has the access for operation

- Dual-channel safety monitoring circuit for double start buttons, safety light curtain, emergency stop button, motor on/off, etc.

- Working & Alarming Indicator: triple color indicating light (green/yellow/red) with an alarming buzzer

Customized-H-Frame-200-Ton-Servo-Hydraulic-Press