Full Automatic High Speed Disposable Face Mask Machine

Full Automatic High Speed Disposable Face Mask Machine

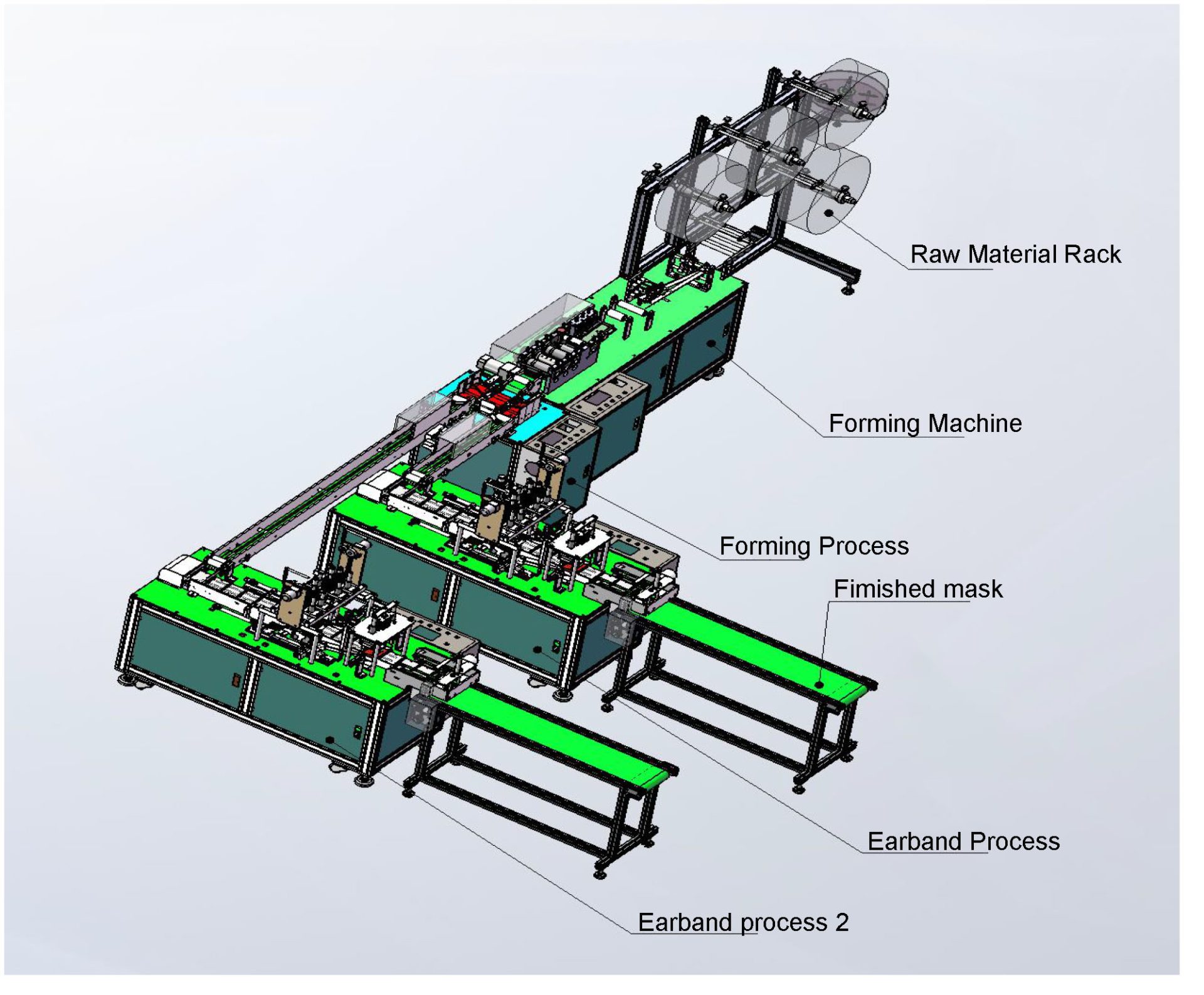

This face mask machine is mainly used for the automatic formation of flat face mask: the entire roll of fabric is driven by rollers after unwinding, and the fabric is automatically folded and hemmed;

the nose beam is pulled and unrolled by the whole roll, cut to length and imported into the hemmed fabric, bilateral Ultrasonic welding to the seal, then ultrasonic side sealing, cutting with a cutter;

Conveying the mask to the two mask ear band welding stations through the assembly line, and finally forming the mask by ultrasonic welding;

when the mask is made, The pipeline is transported to the flat belt line for collection.

face-mask-machine

Here see what face mask machine does the job:

-After the entire roll of fabric is unrolled, it is driven by rollers, and the fabric passes automatic hemming and wrapping of the face mask machine;

-The nose bridge bar is pulled and unrolled, cut to length, and then introduced into the edging fabric. It is ultrasonically welded to the seal on both sides, and then ultrasonically sealed on the side and cut with a cutter

-The face mask is conveyed to the two mask earband welding stations through an assembly line, and the final mask is formed by ultrasonic welding;

-After the mask is made, it is transported to the flat belt line for collection.

face-mask-machine

Face Mask Maker installation and configuration requirements:

(1)Equipment size: 6800mm (L) × 4800mm (W) × 1900mm (H);

(2) Appearance color: aluminum alloy silver, according to this standard without special instructions;

(3) Equipment weight: ≤3000kg, ground load ≤500KG / m2;

(4) Working power: equipment 220VAC ± 5 ﹪, 50HZ, rated power of about 8.8KW;

(5) compressed air: 0.5 ~ 0.7 MPa, using flow rate of about 300L / min;

(6) Operating environment: temperature 10 ~ 35 ℃, humidity 5-35% HR, no flammable and corrosive gas, no dust (cleanness no less than 100,000).

face-mask-machine

Face mask making machine main structure:

| S/N. | Part Name | Qty. | Remark |

| 1 | Water filter cloth / filter cotton / water absorption layer unwinding mechanism | 3 | |

| 2 | Nose bridge strip unwinding mechanism | 1 | |

| 3 | Nose bridge straightening mechanism | 1 | Width 3-7mm |

| 4 | Nose bridge strip driving and cutting mechanism | 1 | Width 3-7mm |

| 5 | Cloth hemming mechanism | 1 | |

| 6 | Roll welding edge sealing mechanism | 1 | Bilateral |

| 7 | Cloth driving mechanism | 2 | |

| 8 | Cloth fan folding mechanism | 2 | |

| 9 | Roll welding side seam mechanism | 1 | |

| 10 | Roll-sealing mechanism | 1 | |

| 11 | Transfer line | 3 | |

| 12 | Shunt | 2 | |

| 13 | Ear band welding machine mechanism | 2 | |

| 14 | Product output | 2 | |

| 15 | operating system | 1 | |

| 16 | Operation panel | 1 |

Incoming materials and product specifications that could be adopted to face mask machine

| Item | Number of hanging shafts | Width(mm) | Coil outer diameter/mm | Barrel inner diameter | Weight |

| Cloth | 3

|

170~200

|

Φ600

|

Φ76.2

|

Max 15kg |

| Nose bridge bar | 1 | 3-7

|

Φ400

|

Φ76.2

|

Max 25kg |

| Ear band | 4 bags | 3 | – | – | – |

Production specifications:

Standard type: 175 * 95mm

Equipment technical parameters:

Production capacity of equipment

(1) Production efficiency: 90-120ppm;

(2) Qualification rate of equipment production: 99% (except that the incoming materials do not meet the requirements, or the employees’ improper operation is excluded)

(3) Equipment failure rate: 2% (refers to the failure caused by the equipment itself)

General equipment configuration and standard requirements

Configuration list of main components

| S/N | Item | Brands | Remark |

| 1 | Pneumatic cylinder | CKD, SMC, AirTac, Chelic,

XINWYANG |

|

| 2 | Solenoid valve | CKD, SMC, AirTac | |

| 3 | Servo motor | VMMORE, THINGET | |

| 4 | PLC | VMMORE/China, Mitsubishi, THINGET | |

| 5 | Bearing | NSK, HCH | |

| 6 | Rail line | STAF, PMI、CPC、AKD | |

| 7 | Optical fiber,

Amplifier |

Omron, Keyence, Panasonic | |

| 8 | Touch screen | WEINVIEW, MCGS, THINGET | |

| 9 | Relay | Omron/Idec | |

| 10 | Press buttons | SHUANGKE Electric |

Specification, wearing parts and random spare parts list

| S/N. | Item name | Specification | Qty | Remark |

| 1 | Tool kit | – | 1 | Debugging tools |

Face-Mask-Machine