Tag Archive for: servo hydraulic press

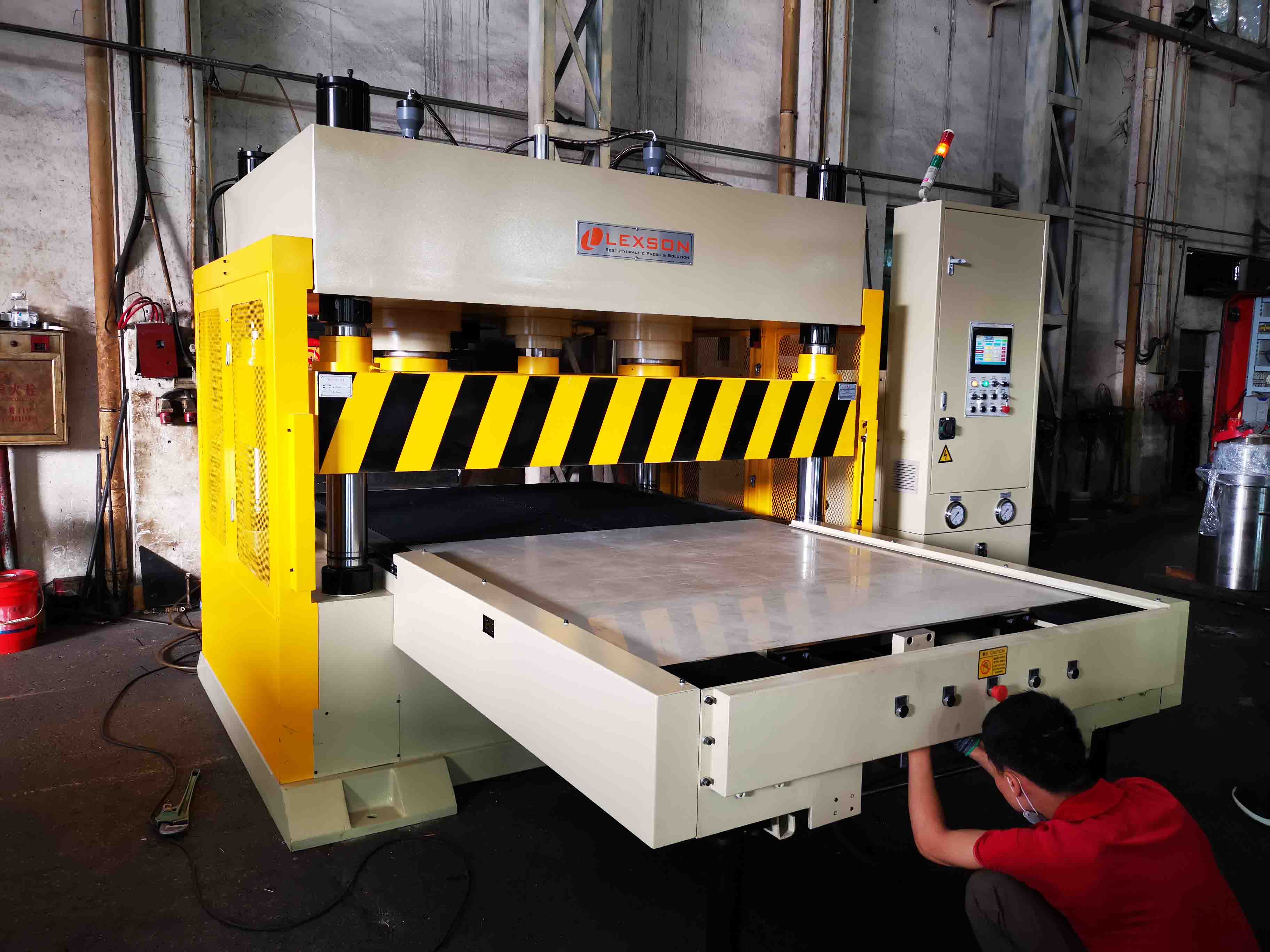

Hydraulic Leather Cutting Machine 200T Pressing Force With Large Table And Shuttle Table

Hydraulic Leather Cutting Machine 200T Pressing Force With Large Table And Shuttle Table

Lexson-A01 PRO 200T Hydraulic Leather Cutting Press ‘s made as Four-post presses, also known as 4-column presses with unilateral shuttle table or Bilateral shuttle table.

This allows the die cutting machine to have working table upto 2000mm, can be even larger.

With the hydraulic cutting press shuttle table, the cut leathers can still be unloaded easily and efficiently out of the hydraulic die cutting press on the shuttle table which ‘s controlled by position sensor.

Besides, Lexson ‘s hydraulic die cutting machine adopts servo motor and servo controller, this made our press a hydraulic and servo-electric presses, that consumes 50-70% less electricity, and more stable pressure (±1bar) and high positioning accuracy(±0.01mm), owe to all these make our hydraulic press cutting machine a no more suitable solution for hydraulic cutting press.

Advantages of 4-Post Hydraulic Leather Cutting Machine:

- Allow secondary adjustment of plate parallelism, that provides the press higher parallelism, which ‘s strictely required by die cutting process.

- Typically more economical than gib-guided presses.

- Allow the press to have large working table, namely the area for cutting ‘s bigger than machine of other types.

- Allow four-sided access to the working area

- Modular design, built to your specifications, even though working table ‘s much bigger other types of machine, due to modular & compact design, it still has small footprint.

Technical specification of Lexson-A01 PRO 200T Hydraulic Die Cutting Machine

| Model No. | Lexson-A01 PRO 200T | Fast Forward Speed | 150~160 mm/s |

| Structure | -4-post hydraulic press

-Top-mounted hydraulic system compact design for less footprint With automatic one OR two shuttle table |

Slow Pressing Speed | 8~15 mm/s |

| Driven | Driven by servo motor + servo controller | Return Speed | 130~140 mm/s |

| Stroke Type | Downward stroke | Parallelism Between Platens | ±0.04 mm |

| Hydraulic Pressure | 20 Mpa | Flatness of Platens | ±0.035 mm |

| Pressure Output | 2000 KN | Power Supply | 3phase 230V 50Hz |

| Standard Stroke | 300 mm | Motor Power | 15 KW |

| Daylight Opening | 300 mm | Approximate Machine Overall Size | 2320*3250*2338 mm (one-side shuttle table) |

| Effective Bed Table Sizes | 1600 (between columns) * 1600 (between edges) mm | 2320*4930*2338 mm (dual-side shuttle table) | |

| Height of Bed Table Above Floor | 850 mm | Approximate Machine Weight | 7,500 KG (one-side shuttle table) |

| 8,200 KG (dual-side shuttle table) |

hydraulic-leather-cutting-machine

Features:

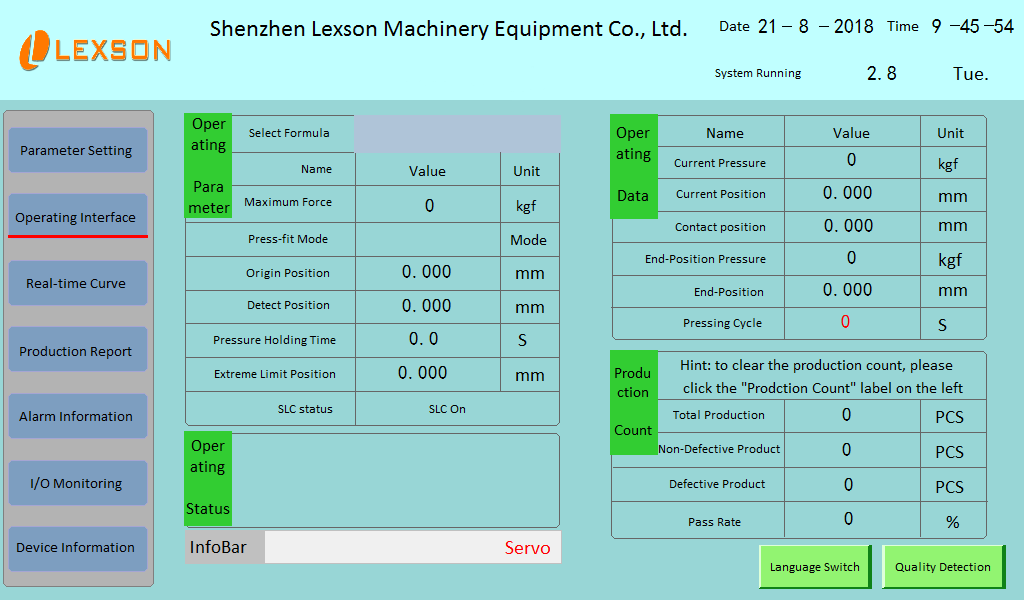

– Omron/Siemens/Allen Bradley PLC control

– Omron/Siemens Color HMI (Human-Machine Interface)

– Pressure Sensor force feedback & Linear position transducer feedback

– Work mode: Fixed Pressure mode & Fixed Position mode

– Smooth and flatbed platen and moving platen

– Automatically lubricating system

– Tricolor(green/yellow/red) operation indicator with warning buzzer

– PLC communication with external equipment (if needed)

– Hydraulic oil cooler

Safety Measures:

– Double start buttons on front side of the shuttle table

– Safety photoelectric light curtain on front and rear side of the bed table, covering the whole daylight open

– Emergency stop button on front side of the shuttle table, manual reset required

– Pneumatic safety ratchet bar to prevent the sudden fall of the slider, in case of any error happened to the hydraulic system

– Interlocked safety mesh shield covers the left/right/rear side of bed table, can be opened and removed. When opened, the motor will shut down automatically, manual reset required

– NEMA style electric control cabinet with electric disconnect switch

– Selector switch with lock, only authorized person has the access for operation

– Dual channel safety monitoring circuit for double start buttons, safety light curtain, emergency stop button, motor on/off, ect.

Available Operation Controls:

– Manual & Auto

– Pressure mode & Position mode switchable

– Stroke adjustable & monitoring

– Pressure adjustable & monitoring

– Speed adjustable & monitoring

– Pressure hold time adjustable & monitoring

– Closed loop electric control

– Specifications programmable on HMI

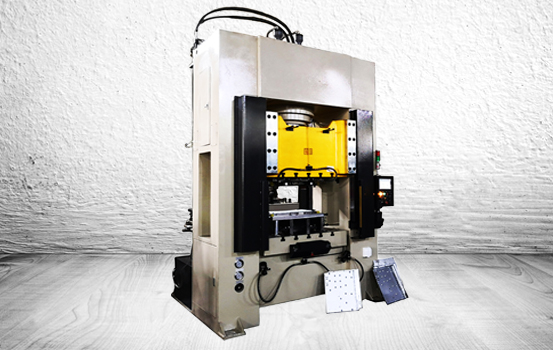

Custom Made C Frame 30 Ton Hydraulic Press Machine

Custom Made C Frame 30 Ton Hydraulic Press Machine

Derive from LEXSON P03 Series C Frame Hydarulic Press, the below LEXSON P03-30 Ton C-frame hydraulic press ‘s built with 10″ HMI that operator can do setting:

- Parameter Setting

- Programmable Pressure

- Pragrammable Stroke

- Programmable Dwell Time

- Moving Bed Table

- Slide Rails for the bed table to move In/Out

- Slide rails driven by Servo Motor with high positioning accruacy

Custom Made C Frame 30 Ton Hydraulic Press Machine under construction

C-frame-30-ton-hydraulic-press-machine

LEXSON P03 C Frame 30 Ton Hydraulic Press Machine Technical Specification

| Model | LEXSON-P03-30 Ton | Bed Table | 600*500 mm |

| Daylight Opening | 800 mm | Slide Table | 400*300 mm |

| Cylinder Stroke | 600 mm | Slide Bed Table Stroke | 600 mm |

| Motor | 3 Phase, 380VAC, 50Hz | Motor Rate | 5.4 KW |

custom-made-C-frame-30-ton- hydraulic-press-machine

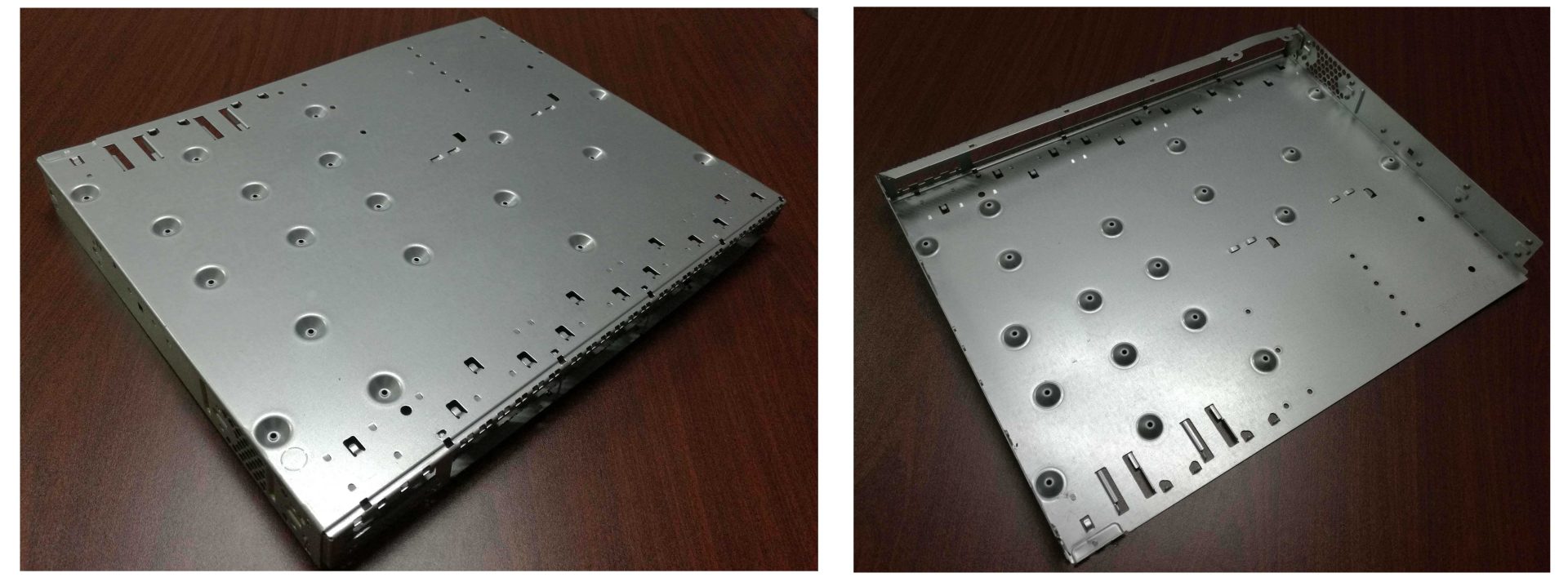

Metal Stamping Press Machine – Lexson Press Made In China

Metal Stamping Press Machine – Lexson Press Made In China

LEXSON provides a full range of H frame metal stamping press machine from 50 ton up to 1000 ton, that utilizes advanced Servo Hydraulic Press System with the following features:

- PLC control, for high precision control

- 10 Inches Color HMI

- Pressure repeat accuracy: ±1%

- Plates parallelism: ±04%

- Table flatness: ±025 mm

- Load Sensorforce feedback & Linear position transducer feedback

- Work mode: Pressure mode & Position mode

- T slotted bed platen and moving platen for mold locking

- Automatic lubrication system

- PLC communication with external equipment

- Programmable operation

- 50-70% less power consumption than a conventional hydraulic press

- Much lower oil temperature in the working condition than a conventional hydraulic press

- Top mounted hydraulic system

- Lifting rings on the top plate for easier machine locating

metal stamping press machine

With LEXSON ‘s servo-hydraulic system, LEXSON ‘S presses are more advantageous in:

- Faster velocity

- Full adjustable velocity

- Adjustable pressure control

- Adjustable slide position

- Requires significantly less maintenance than a conventional hydraulic press

metal stamping press machine

Safety Measures:

- Double start buttons on the front side of the bed table

- Safety photoelectric light curtain on the front side of the bed table, covering the whole daylight open

- Emergency stop button on the front side of the bed table, manual reset required

- Pneumatic safety ratchet bar to prevent the sudden fall of the slider, in case of any error happened to the hydraulic system

- Adjustable protective mechanical position limit switch

- Interlocked safety mesh shield covers the left/right/rear side of bed table, can be opened and removed. When opened, the motor will shut down automatically, manual reset required

- NEMA style electric control cabinet with electric disconnect switch

- Selector switch with lock only authorized person has the access for operation

- Dual-channel safety monitoring circuit for double start buttons, safety light curtain, emergency stop button, motor on/off, etc.

- Working & Alarming Indicator: triple color indicating light (green/yellow/red) with an alarming buzzer

metal stamping press machine

Customized H Frame 200 Ton Servo Hydraulic Press

Customized H Frame 200 Ton Servo Hydraulic Press – Ideal Metal Forming Press Machine

Lexson-P04 PRO customized H frame 200 ton servo hydraulic press is the ideal metal forming press machine for automobile parts and other precision parts. We are dedicated in design and manufacturing of a full range of Servo Hydraulic Press and pure hydraulic press from 100 to 3000 ton.

With our servo hydraulic system, our presses more advantageous in:

- Faster velocity

- Full adjustable velocity

- Adjustable pressure control

- Adjustable slide position

- Less maintenance than a conventional hydraulic press

servo driven hydraulic press

200 Ton Servo Hydraulic Press features:

- PLC control, for high precision control

- 10 Inches Color HMI

- Load Sensorforce feedback & Linear position transducer feedback

- Work mode: Pressure mode & Position mode

- T slotted bed platen and moving platen for mold locking

- Automatically lubricating system

- PLC communication with external equipment

- 50-70% less power consumption than a conventional hydraulic press

- Much lower oil temperature in the working condition than a conventional hydraulic press

customized 200 ton servo press

Safety Measures:

- Double start buttons on the front side of the bed table

- Safety photoelectric light curtain on the front side of the bed table, covering the whole daylight open

- Emergency stop button on the front side of the bed table. Manual reset required

- Pneumatic safety ratchet bar to prevent the sudden fall of the slider. As a result, the avoidance of pending peril will be a great possibility.

- Adjustable protective mechanical position limit switch

- Interlocked safety mesh shield covers the left/right/rear side of bed table, can be opened and removed. When opened, the motor will shut down automatically. Manual reset required

- NEMA style electric control cabinet with electric disconnect switch

- Selector switch with lock only authorized person has the access for operation

- Dual-channel safety monitoring circuit for double start buttons, safety light curtain, emergency stop button, motor on/off, etc.

- Working & Alarming Indicator: triple color indicating light (green/yellow/red) with an alarming buzzer

Customized-H-Frame-200-Ton-Servo-Hydraulic-Press

Servo Hydraulic Press Machine VS Conventional Hydraulic Press Machine

Servo Hydraulic Press Machine VS Conventional Hydraulic Press Machine

The servo hydraulic press machine is a servo-driven hydraulic press system integrated with the precision pressure and position transducer for closed-loop control. Compared to conventional hydraulic press, the advances of the servo hydraulic presses are obvious:

- First of all, much faster approaching, pressing and return speed

- Speed adjustable during the whole stroke

- Pressure repeat accuracy: ±1%

- Furthermore, 30%~60% lower energy consumption

- Much lower noise level

- All parameters programmable on the central color touchscreen

- High degree of reliability and minimum need for maintenance during the entire lifetime

servo-hydraulic press machine VS conventional hydraulic press machine

Application of Lexson servo hydraulic press

Precision force control and real-time production monitoring make the servo-hydraulic press the ideal machine equipment for most of the precision applications such as automobiles parts forming and assembling, motor bearing assembling and press fitting, the electric connector assembly, and press fitting, as well as the precision straightening, trimming, compression molding and so on. As with powerful lower energy consumption, the heated platen servo-hydraulic press is born to be the perfect press machine solution for hot compression molding application with long pressure holding time.