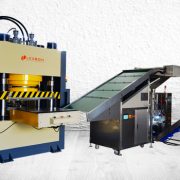

600 ton jigsaw puzzle cutting machine, four-post puzzle cutter high-end automatic puzzle production line

600 ton jigsaw puzzle cutting machine, four-post puzzle cutter high-end automatic puzzle production line

LEXSON is a leading brand of jigsaw puzzle cutting machine and is well-known by jigsaw puzzle making makers from all over the world.

Advantages of Lexson-A01 PRO 600T puzzle cutting machine:

The frame of 4-column 3-plate design provides high-grade parallelism between the slider and slider bed, that is where good cutting from.

Hydraulic pipe system uses integrated manifold block fits inside the press to reduce piping and oil leaks.

Operated by a two-handed start button.

Selector switch modes of operation: jog (setup) and run (cycle).

Flexibly adjustable of pressure dwell time and stroke.

The ideal of double SLC(Security Light Curtain) makes it safe for operation.

Front Side Covers with emergency switches;

A protective fence and a safety interlock can be added to upgrade the security.

All pipes, flanges, and joints with vibrations proof and leakage proof design and setting.

Automatic computerized slider rails lubrication.

Adjustable sliding rails for cutting die to slide in & out.

puzzle cutting machine

Jigsaw puzzles have been a favorite pastime for children and adults alike since their creation in 1762. Although they were originally handmade from wood, most jigsaw puzzles nowadays are made from the more economical—and easier to mass-produce—paperboard, but acrylic, wood, and plastic are also used. In the early 20th century, Jigsaw puzzle companies used large hydraulic puzzle cutting machine, to manufacture jigsaws, but the more economical roller press manufacturing process soon took over, and, more recently, newer technology has brought the laser-cutting puzzle-making process into the picture. Puzzles can be anywhere from four to 50 pieces for younger children, and go up to over 40,000 pieces. In addition to the standard flat puzzles, 3D puzzles made from wood or Styrofoam are also gaining popularity, as well as word puzzle games, and computer-based jigsaw puzzles.

puzzle cutting machine

Therefore, the demand for puzzles on a global scale has increased sharply. At the same time, LEXSON produced and launched a 600-ton-based puzzle machine, puzzle cutter, puzzle making machine, puzzle cutting machine that can produce 200pcs to 1500pcs puzzles, Lexson-A01 pro 600T puzzle machine, and LEXSON-ISB-G01 the first generation of puzzle break-up unit, scattering machine and automatic packaging machines, puzzle bagging machines that are welcome by our customers and trusted by puzzle manufacturers all over the world.

LEXSON currently sells to global customers including the United States, Malaysia, Australia, Japan, Brazil, the United Kingdom, France, Poland, Czech Republic, and Egypt.

In order to meet the needs of our customers to produce larger size puzzles, LEXSON has developed larger puzzle machines that can produce more than 1500 pcs and larger than 1000x1000mm. These are the Lexson-A01 pro 800T puzzle cutting machine and the Lexson-A01 pro 1000T puzzle cutter machine. All of the above models can be made to have servo-driven shuttle table that can increase production safety and efficiency. The above machines can be incorporated into Lexson ISB G01 incline scatter and vertical automatic packaging machine in the machine layout. The machine connection is flexible, the production efficiency is high, and only one person can operate a production line.

Main technical specifications:

| S/N | DESCRIPTION | UNIT | SPECS | |

| 1 | Master Cylinder Nominal Force | ton | 600 | |

| 2 | Hydraulic system pressure(Max.) | MPa | 25 | |

| 3 | Max. Stroke | mm | 200 | |

| 4 | Daylight Opening | mm | 200 | |

| 5 | Cylinder Speed | Close | mm/s | 250 |

| Slow Clamp | mm/s | 5-10 | ||

| Open | mm/s | 250 | ||

| 6 | Slider Bed Height | mm | 1050 | |

| 7 | Slider Bed | L-R | mm | 950 |

| F-B | mm | 900 | ||

| 8 | Approx Machine Dimensions | L-R | mm | 2168 |

| F-B | mm | 2852 | ||

| Height | mm | 2768 | ||

| 9 | Motor Power | kW | 33 | |

| 10 | Approx machine weight | kg | 16500 | |