Puzzle Making Machine – 600T, 800T, 1000T, 2000T Puzzle Machine leading brand LEXSON

Puzzle making machine – 500 ton, 600 ton, 800 ton, 1000 ton, 2000 ton Puzzle Machine leading brand LEXSON

A jigsaw puzzle is produced by a puzzle making machine, which is hydraulic driven, is a tiling puzzle that requires the assembly of often oddly shaped interlocking and mosaiced pieces. Typically, each individual piece has a portion of a picture; when assembled, they produce a complete picture.

Typical images on jigsaw puzzles include scenes from nature, buildings, and repetitive designs—castles and mountains are common, as well as other traditional subjects. However, any kind of picture can be used. Artisanal puzzle-makers and companies using technologies for one-off and small print-run puzzles utilize a wide range of subject matter, including optical illusions, unusual art, and personal photographs. In addition to traditional flat, two-dimensional puzzles, three-dimensional puzzles have entered large-scale production, including spherical puzzles and architectural recreations.

puzzle making machine

In recent years, a range of jigsaw puzzle accessories including boards, cases, frames, and roll-up mats has become available to assist jigsaw puzzle enthusiasts.

While most assembled puzzles are disassembled for reuse, they can also be attached to a backing with adhesive and displayed as art.

puzzle making machine

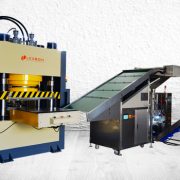

Most modern jigsaw puzzles are made of paperboard as they are easier and cheaper to mass-produce. An enlarged photograph or printed reproduction of a painting or other two-dimensional artwork is glued to cardboard, which is then fed into a press. The puzzle press, puzzle machine, puzzle making machine forces a set of hardened steel blades of the desired pattern, called a puzzle die, cutting die, steel rule die, through the board until it is fully cut.

The puzzle die is a flat board, often made from plywood, with slots cut or burned in the same shape as the knives that are used. The knives are set into the slots and covered in a compressible material, typically foam rubber, which serves to eject the cut puzzle pieces.

The cutting process is similar to making shaped cookies with a cookie cutter—however, the forces involved are tremendously greater: A typical 1000-piece puzzle requires upwards of 700 tons of force to push the die through the board.

In order to meet the greater demand for jigsaw puzzle products in the global market today, and to improve the production efficiency of puzzles, LEXSON not only produces large-scale Puzzle making machines but also develops jigsaw puzzle breakup units and automatic bagging machine. After the puzzle is punched, the puzzle can be directly pushed to the conveyor. The breakup unit is driven by a servo motor, which can fully break up the puzzle, and then enter the funnel and automatically fall to the automatic bagging machine.

puzzle making machine

Main technical parameters

| S/N | DESCRIPTION | UNIT | SPECS | |

| 1 | Master Cylinder Nominal Force | ton | 600 | |

| 2 | Hydraulic system pressure(Max.) | MPa | 25 | |

| 3 | Max. Stroke | mm | 200 | |

| 4 | Daylight Opening | mm | 200 | |

| 5 | Cylinder Speed | Close | mm/s | 250 |

| Slow Clamp | mm/s | 5-10 | ||

| Open | mm/s | 250 | ||

| 6 | Slider Bed Height | mm | 1050 | |

| 7 | Slider Bed | L-R | mm | 950 |

| F-B | mm | 900 | ||

| 8 | Approx Machine Dimensions | L-R | mm | 2168 |

| F-B | mm | 2852 | ||

| Height | mm | 2768 | ||

| 9 | Motor Power | kW | 33 | |

| 10 | Approx machine weight | kg | 16500 | |